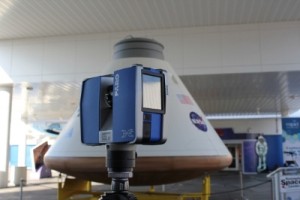

3D Technology companies Lockheed Martin, FARO, Direct Dimensions, Met-L-Flo, Florida Institute of Technology and Cincinnati Inc. have collaborated to take a 3D scan of the Orion spacecraft crew module for the RAPID 2016 event organised by SME.

The digital model will be used to 3D print approximately 150 small-scale replicas of the NASA spacecraft, which will be displayed and handed out at the RAPID event.

The Orion spacecraft can carry a crew of four astronauts to destinations at or even beyond low earth orbit. It has been created to explore asteroids and Mars along with the purpose of delivering and retrieving crew or supplies from the ISS. Although a successful test flight has taken place in 2014, the first mission to carry astronauts is expected to take place in 2023.

“Additive manufacturing and 3D printing technologies are widely used to produce aerospace and other high-performance products,” said Carl Dekker, president of Met-L-Flo. “It is exciting that we are using 3D scanning and additive manufacturing to reproduce 3D models of the Orion—a spacecraft which may carry these technologies to other planets.”

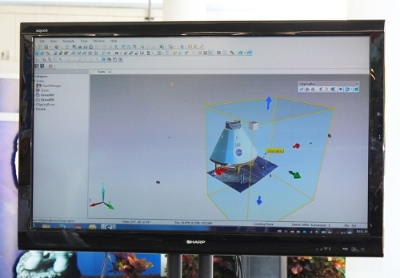

The 3D laser scan of the crew model was performed by FARO, while Direct Dimensions will prepare the module for 3D printing through Met-L-Flo. Additionally, Cincinnati Inc. will be using their Big Area Additive Manufacturing (BAAM) technology to 3D print a replica of the spacecraft onsite RAPID 2016.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.