Conventional 3D printers use UV-light together with another light source to harden resin. A short time ago an alternative to the slow conventional techniques was announced: CLIP. Now Photocentric has developed an alternative to CLIP that has its own advantages.

The UK-based company Photocentric has developed a new technique to harden resin more easily. Therefore they use LCD-screens that are also used in Smartphones to harden their resin. The new resin only needs the light that’s emitted from the LCD to cure.

The concept is simple – use the daylight emitted from an LCD screen to polymerize resin that is tailored to that wavelength and intensity. All other 3D printers that polymerize resin use a combination of both daylight and UV light at considerably higher intensities

Photocentric is a known developer and producer of resin. The company produces over 500 tons of the material each year. Since 13 years they produce resin and they have 75 employees now. The key of their newly developed 3D printer is, it’s no surprise: The resin. The newly developed High-Tec resin hardens with the light from the LCD Screen. It took them nearly 3 years to develop the resin and the 3D printer. It’s no wonder that their new technique is already patented by them.

The LCD screens that are used by smartphones have some big advances for this kind of 3D printer. The screens have relatively high brightness and a very high resolution. Furthermore these screens are already developed and produced – so they are not expensive as other solutions. For the beginning Photocentric has announced two different 3D printers: The LIQUID CRYSTAL 10” Daylight Polymer and the LC Mini 3D printer.

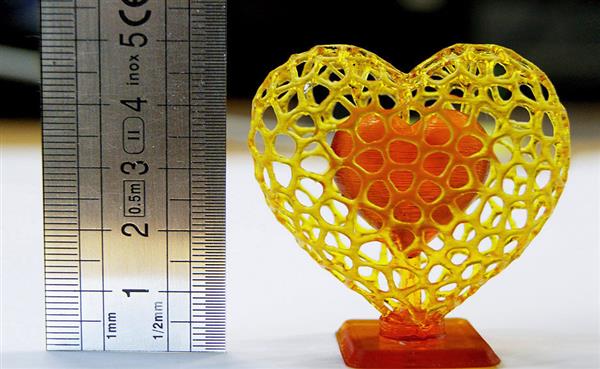

The LIQUID CRYSTAL 10” Daylight Polymer has a build area of 200x100x200 mm and the smaller brother has a build area of 60x100x120 mm. Both printers have a layer height of 25 microns. The bigger one costs £699 ($1000 USD) and the smaller 3D printer costs £449 ($750 USD). The 10” 3D printer can already be purchased through the company’s website. The 10” printer has a XY resolution fo 220 microns and needs 28 seconds per layer.

The speed and the grade of detail that’s possible with this technology are fairly interesting. The 10” printer uses an LG 9.7″ 2048×1536 retina display for testing purpose. With this display an XY resolution of 100 microns is possible – but this display is not as bright as displays with worse quality. Because of that the layer time is “high” with 55 seconds but the grade of detail that’s achievable is very astonishing.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.