3D technology and its production potential truly fascinate collective imaginary. Up till now, creating an efficient production system was unthinkable. IRA3D worked hard to achieve this objective and now it has succeeded and has launched the new 3D printer with FLD technology: Poetry4.

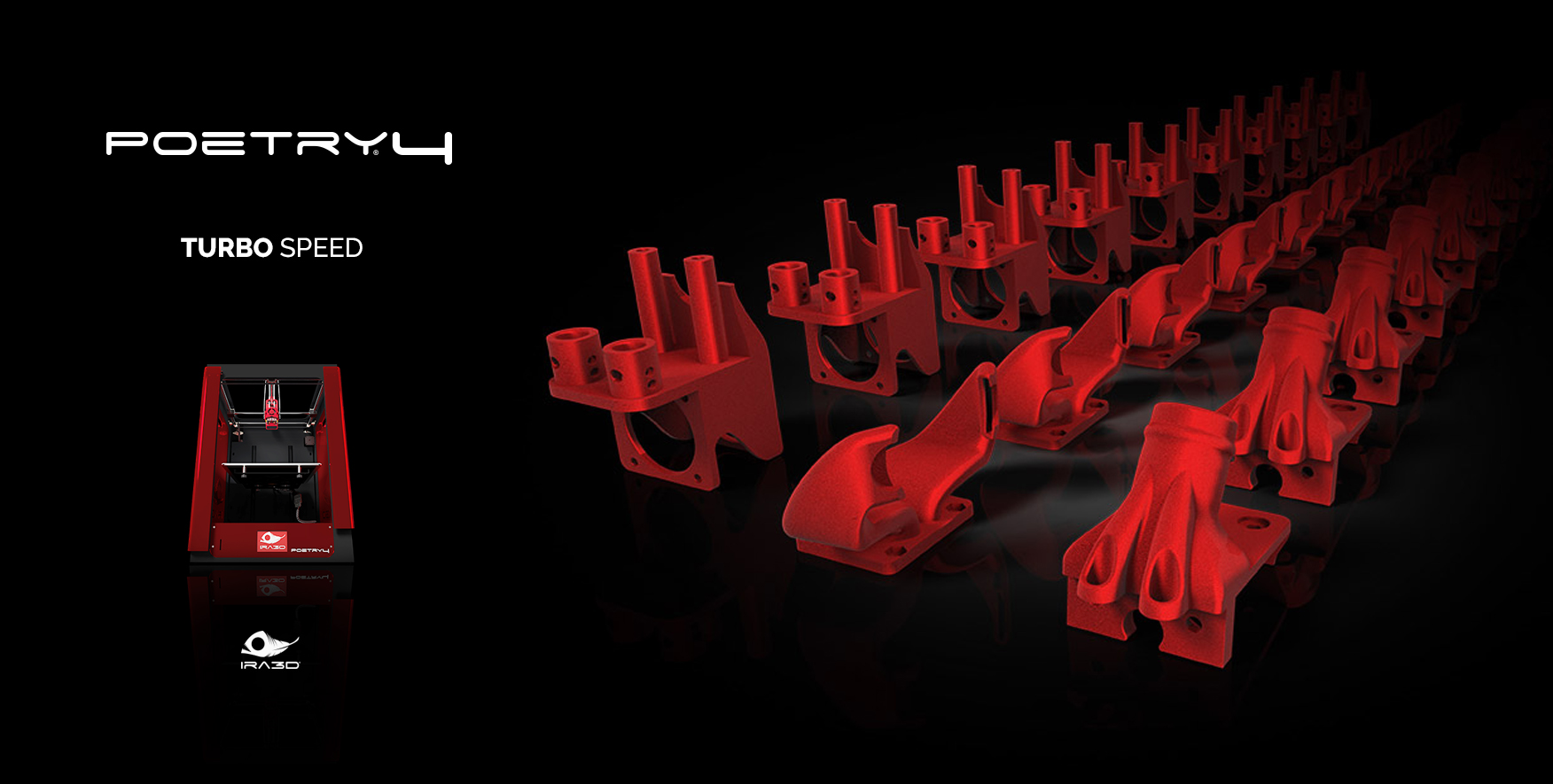

Mass production is the creation of large quantities of products, one of the objectives of Poetry4, IRA3D’s latest addition. The use of 3D printing by manufacturing and design companies has become increasing more frequent and is now expanding to the architecture, construction, defence and biomedical sectors, just to mention a few.

Time is money, and the Poetry4 printer with advanced FLD technology is developed for professionals and amateurs wishing to achieve perfection quickly. Thanks to state of the art engineering, the perfectly tooled gearing and the development of a special motherboard, Poetry4 is incredibly fast compared to market standards and is the perfect tool to create prototypes, samples, scale projects, finished products and mass productions.

All the finishes of Poetry4 new print heads, the bobbin holders and the new air conveyors that are used in all Poetry4 printers, have been mass produced using Poetry4.

Poetry4 is the 3D printer designed to meet the requirements of anyone in need of a professional tool to create not just prototypes, but also finished products or small/medium-size mass productions.

The reliability of the new extruder and Turbo Speed system, implemented on all Poetery4 printers, provide a stable production system that meets 3D printing quality and mass production requirements.

Printing an object requires a very accurate planning process involving both the 3D file and printing job, a 3D design, defining the production cycle (positioning and optimal number of pieces); slicing definition to achieve the right layer definition and obtain the best response to strains, reducing the stress during the printing process; analysis of the materials (each material has its own characteristics that can dictate specific project choices) and the creation of supports required to guarantee the quality of the printed object (ensure the geometry and shape, for example, the definition of curved or angled parts), without forgetting the removal stages, material characteristics and the post-processing and finishing stages.

To facilitate this process Poetry4 has been equipped with new important features:

The new heated print bed, with Easy Build system, that doesn’t require the use of lacquer, spray or glue, for an easy and reliable printing process. Additionally, Easy Build’s optimised heat management system ensures the perfect adherence of the printed object to the plate, drastically reducing the chance of printed items deforming due to loss of adherence. A 250x250x300 mm printing area to create projects, prototypes and finished products, without space restrictions.

Snap: the new print head equipped with dual extruder, 2 hot-ends and just 1 radiator: the optimised heat management system, which keeps the temperature of the nozzles constant, ensures stability and reduces vibrations, depositing layers of material up to 15 micron thick (0.015mm); ventilation is better convoyed towards the extrusion area, allowing for more precise results and more detailed undercuts.

The new Self Grip extrusion system automatically applies the correct pressure to the filament, preventing it from getting damaged during printing and using the right calibration for the type of material selected. Additionally, Self Grip requires no calibration, simplifying filament extrusion. To offer the best possible printing results Ira3D has created the Poetry Filaments range, which includes classic, soluble, architectural, experimental and metal compound materials.

Mass 3D printing has huge advantages, as one single process allows to create identical pieces as well as different personalised objects, without having to change flow, equipment or re-programme production tools: this is what Poetry4 is for.

The market is feverish and companies are just waiting for 3D printing to take over and transform production processes, creating a real industrial revolution.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.