United Utilities and ChangeMaker 3D have achieved a first in the UK water industry by demonstrating the use of 3D concrete printed components – with significant carbon, cost and labour savings. The trailblazing move sees the water sector taking the lead in the development of the new tech known as ‘Printfrastructure’.

During a 12-month period, ChangeMaker 3D worked in partnership with United Utilities to successfully design, 3D-print and install a wastewater chamber at one of the utility company’s test facilities in Cheshire. With testing now complete, the partners say it proves the huge potential of 3D printing for construction and could lead to widespread benefits for other sectors.

In the case of the water chamber, ‘Printfrastructure’ delivered a 25% reduction in carbon, 20% cost saving and 55% reduction in labour versus traditional methods. The team also point to the extremely fast build time – the chamber was printed in under four hours, and with a significant reduction in the materials used. The printing process for the water chamber has also demonstrated safety benefits by reducing the requirement to work at height or in confined spaces.

United Utilities’ Chief Engineer (Innovation), Lisa Mansell said: “This is important for us in realising our aim to drive efficiency and improvement in everything we do for the benefit of our customers. The future is exciting for water companies like United Utilities who are trailblazing innovation. We have a huge capital programme to deliver under tight deadlines. Digital technologies such as 3D construction printing can drive efficient construction and help us meet our Net Zero goals for carbon.”

Natalie Wadley, Co-Founder and CEO of ChangeMaker 3D, said: “After months of hard work, we are thrilled to see the water chamber in situ, with proven environmental and cost benefits. It’s the result of a brilliant collaboration with United Utilities and our team of delivery partners, including CyBe Construction, Costain, Constructure, Ainscough and AutoMutatio. Thanks to them, we have achieved several UK ‘firsts’ – including the design, print and installation of a 3D concrete printed component for this sector, and the UK’s first crane lift of a 3D printed structure.

“Our mission is to support industry to leave a lighter footprint, and transforming the UK’s infrastructure is critical if the UK is to reach ‘Net Zero’. We believe 3D printed concrete has the potential to help deliver the green growth our country needs. Our aim now is to continue to work with United Utilities to grow the impact. We want to prove this is a technology that can have widespread uses not just in the water sector, but for rail and highways, too.”

The partners have released a video, ‘Printfrastructure – Together for a Net Zero Future’, which documents the journey of the chamber from concept to testing. It shows how the collaboration came about – driven by shared sustainability goals – and helps viewers get to grips with 3D printing technology.

ChangeMaker 3D was selected for United Utilities’ Innovation Lab at the start of 2021 – a highly regarded competition in which new ideas are incubated and brought to market. During a 12-week design sprint, they worked with the company to identify the best component to design and demonstrate. The team selected a wastewater distribution chamber – providing enough technical challenge, together with the opportunity to bring a more sustainable approach to a component which has traditionally been carbon heavy.

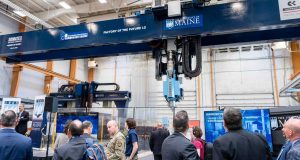

Supported by the Lab’s wealth of expertise and resources, the team created an accurate digital model of the 1.8m cylindrical chamber. This was then printed offsite in a factory by Dutch technology partners, CyBe Construction. Natalie explained that the process involves piping 3D mortar through a robotic arm to a precise computer design – a bit like icing a cake. The chamber was craned into position at its new home in Cheshire earlier this year, where further testing has since taken place.

Lisa added: “Through the process, we’ve been able to carry out all the rigorous testing we would want around strength, durability and water tightness. This is important for giving our construction partners comfort around the new technology, because ultimately, we’ll be asking some of them to adopt it.

“We’ve also had the benefit of sharing best practice with ChangeMaker 3D’s other cross-sector partners including HS2,” she added. “By learning together we’re pushing ourselves further for the benefit of the whole of the UK.”

ChangeMaker 3D co-founder Luke Wadley believes the technology will help young people build skills for the future saying: “We have an opportunity to educate and inspire young people to come forward and discover the industry. This technology has scope to open up new careers in digital and future construction. It’s what we’re passionate about.”

And Lisa agreed, adding, “In terms of developing young people and increasing skills in the sector, this is totally aligned to United Utilities’ social value goals. This fantastic collaboration can help us achieve this.”

Find out more about United Utilities at unitedutilities.com.

For more information about ChangeMaker 3D, please visit changemaker3d.co.uk.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.