Printr, the Amsterdam-based company taking cloud 3D printing by storm, has introduced a new technology that creates efficient and clean dual extrusion 3D prints by producing one or multiple smart wipe towers in the shape of a donut.

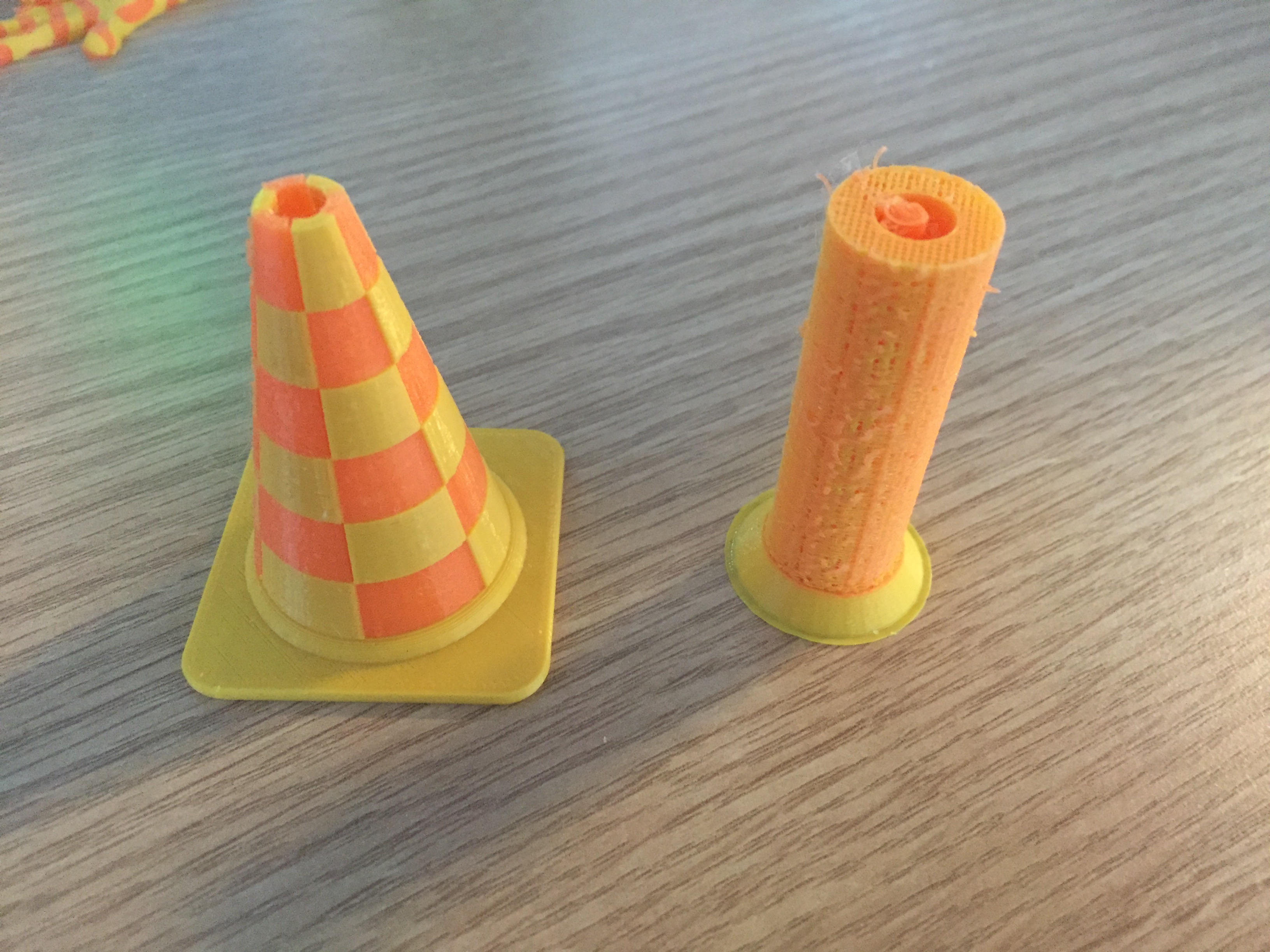

If you’ve ever printed a model which requires dual extrusion, you’d know that the main challenge lies in getting your print as clean as possible, without blemishes or color blending. To reduce this problem, a ‘wipe tower’ is usually created near the model, where extruders can wipe off the excess filament that may accidentally blend during dual color printing. Whereas various slicers offer dual extrusion and create solid wipe towers, Printr’s cloud slicer Katana, embedded in Formide, is the first slicer to enable the production of so-called ‘Donut wipe towers’ for multi-extrusion. These new and improved hollow towers now enable faster and more efficient printing, and exceptionally clean dual prints.

Donut wipe towers: Efficiency and Effectiveness

Due to its shape, the Donut wipe tower is much more efficient in time and material. As the extruder skips the middle part of the wipe tower and only prints the outline of the donut, it does not use as much filament compared to a regular wipe tower and thus, saves printing time. As the Donut wipe tower has a bigger base on the print bed, it is also much more stable than regular wipe towers and is thus less likely to accidentally tip over during printing.

Moreover, usually extruders have a tendency to start leaking filament before they reach the set temperature, creating a messy print. Inspired by BCN’s Independent Dual Extruder (IDEX) trays for material leakage, Printr has designed the dual extrusion process in a way that extruders only heat up in the hollow part of the Donut wipe tower. This way possible filament leakage occurs in the hollow part of the wipe tower instead of on the print bed, resulting in a very clean printing process. If users would like to optimise their time and material usage even more, they are able set a specific infill percentage for their Donut wipe tower. Users that print with two types of less compatible material, such as PLA and PVA, can choose to create two separate wipe towers on the print bed. This all makes for a more efficient printing process and cleaner prints; a win-win situation.

Automatic detection

Formide’s built-in cloud slicer Katana is designed to be smart, detecting whether the 3D model requires a complete wipe tower at the whole model or just part of it. For example, if you have a dual extrusion model and only need to print the bottom 40% of the model in dual colors, Katana will automatically detect this and stop the Donut wipe tower after the dual colored part has been printed. Moreover, if a 3D model contains a single color at the bottom and dual colors at the top, Katana will also automatically detect this and create the bottom of the wipe tower in a single color. This way no unnecessary extruder switching, and thus heating, is done.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.