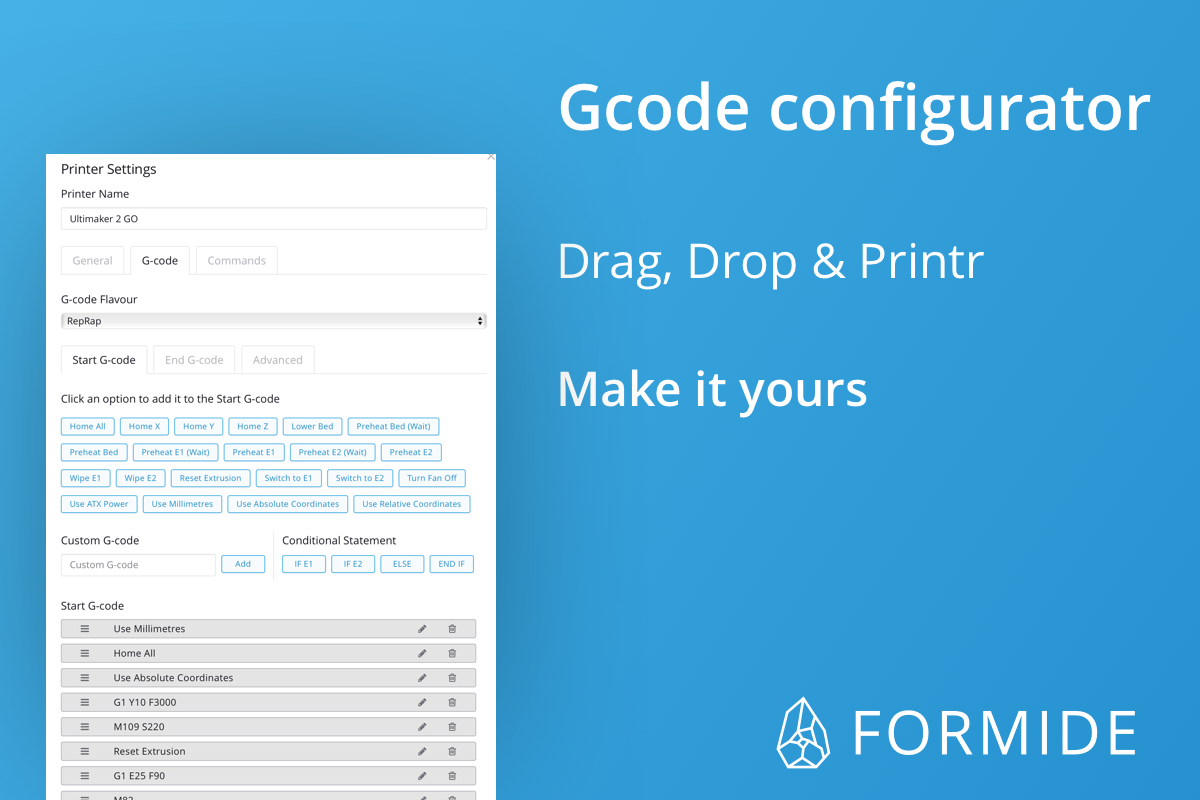

Printr, the Amsterdam-based company renowned for online platform Formide, has introduced a new feature that enables users to create custom Start and End Gcodes with drag and drop tiles.

If you’ve ever tried to create custom start- or end Gcodes on any slicer, you’d know that the main challenge lies in understanding what each Gcode command does and combining them into a functioning instruction for the printer. A quick search through popular 3D printing forums reveals the struggles users have with accidentally removing a Gcode and not knowing how to revert it. On top of that, 3D printers with edited firmware bring the challenge of having to figure out how to apply printer specific Gcode commands. To eliminate these problems, Printr launched the Gcode Configurator on online platform Formide. This new feature enables users to edit existing Gcode sequences or create custom Gcode sequences from scratch by selecting their desired behavior from a list of Gcode tiles. All of this without touching a single line of code. In case you do not want to build your own Start Gcode, Formide’s database also includes a standardized start- and end Gcode for each printer.

Increased Efficiency

Similar to Printr’s preconfigured slice profiles in cloud-slicer Katana, the Gcode configurator is built in line with the notion of lowering the technical barriers to 3D printing. Above all, it’s built with efficiency in mind. For instance, if you have a dual extrusion 3D printer, chances are that your printer’s Gcode is written to preheat both extruders even when you are planning to use only one. However, within Formide’s cloud-slicer Katana, users are able to select which extruder they want to use for printing the brim, skirt and support respectively or even for different models on the printbed. Based on users’ indicated settings, Katana creates a start Gcode for that specific extruder setup. In doing so, Katana prevents extruders from preheating when they don’t have to. This in turn prevents cases of filament leakage or filament carbonization in the bottom of non-active extruders. Ultimately, this makes for a faster and more energy and material efficient 3D printing process.

Advanced, yet simple

In simplifying the process of configuring Gcode, Printr’s CTO Chris ter Beke didn’t want to completely eliminate the ability for users to deep dive into code and write custom start- or end Gcode. In the ‘advanced’ tab of the configurator, users have the complete freedom to edit or customize the plain text of the Gcode to their liking. Although the front-end of the configurator displays a small number of tiles, many one of the tiles represent a complex chunk of code. For instance, the ‘Wipe E1’ tile checks whether the extruder is used in the printer. If so, it heats up the extruder, waits for it to be warm and subsequently calculates the width of the wipeline. Based on this calculation it extrudes the perfect wipeline for your 3D printer. It’s the first time a slicer adds this much functionality by simply adding a tile to the Gcode configuration.

Make it yours today

If you want to experience the ease of Formide’s Gcode configurator, all you have to do is create an account on Formide.com, set up your 3D printer and the respective start- and end Gcode. Want to check the result of your Gcode? Just slice your model and download your Gcode for free. Please check the video and see one of the many examples of how you can use the Gcode configurator.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.