Manufacturers of smart medical devices, smart robots and other products with smart sensors could simplify their device design and manufacturing with a patent-pending method from Purdue University that combines piezoelectric poling of filament and 3D printing in a single process.

Traditional sensor materials have piezoelectric properties but are not suitable for 3D printing. Polyvinylidene difluoride (PVDF) filament used in 3D printing has weak piezoelectric properties. As a result, electrical poling must be performed in a post-processing phase, increasing time and cost.

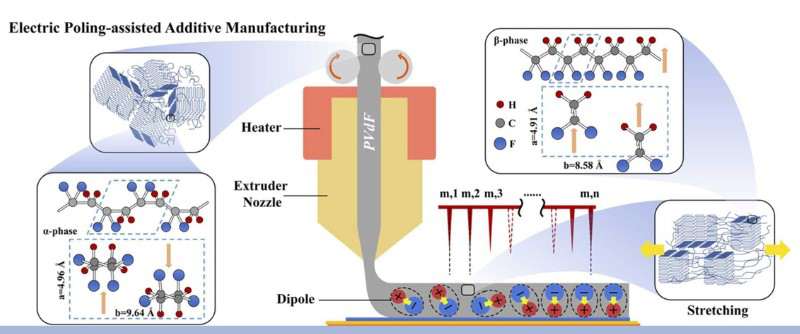

A team at Purdue Polytechnic Institute developed the electric poling-assisted additive manufacturing (EPAM) process, which combines 3D printing and electric poling. This results in the alignment of dipoles in the PVDF filament during printing, giving 3D-printed parts strong sensory capabilities and custom shapes while saving time and money.

“During the EPAM process, stretching the molten PVdF rod rearranges the amorphous strands in the film plane, and the applied electric field aligns dipoles toward the same direction,” Nawrocki said. “The EPAM process can print free-form PVdF structures and induce the formation of β-phase, which is primarily responsible for the piezoelectric response.”

In collaboration with Jose M. Garcia-Bravo and Brittany Newell, and Ph.D. student Jinsheng Fan, they successfully printed PVdF force sensors using a fused deposition modeling 3D printer and a corona electrical poling structure.

“The piezoelectric activity, measured in picocoulombs per newton, or pC/N, was calculated based on the piezoelectric output voltage,” Nawrocki said. “The average piezoelectric activity of EPAM-printed PVdF films was 47.76 pC/N, or about five times higher than unpoled 3D-printed films, at 9.0 pC/N. The piezoelectric activity of unpoled 3D-printed PVdF films indicated that 3D printing in the absence of an electric field did not result in dipole alignment.”

Find out more about the Purdue University at purdue.edu.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.