Today, it is the norm for many products – gadgets, toys, home furnishings and even furniture – to have very short shelf lives of sometimes just a few weeks. Huge amounts of electronics and plastic waste is created which often ends up in landfill or even our oceans. Here in the UK, reduced demand has led to significant falls of 25% in the price of some recycled materials in the last 12 months, the likelihood of this to change in the short term is small. At the same time, there is considerable wasted effort undertaking parallel research and development as individuals and businesses compete for market share. Rather than working to enable incremental innovation, patents often block it. Globalisation has shifted jobs and opportunity to low cost base manufacturing locations which means that the very customers who were previously made up the markets no longer have less to spend on non essential products.

Driven by the desire to overcome these challenges, Buzz Technology have been working to come up with the elements of an ecosystem that should prove better for everyone – consumers, workers, innovators and investors. The company will be showing some of it’s innovations in 3D printing, robotics, packaging and a sophisticated sharing economy platform at it’s ‘Enabling Equality’ stand at the upcoming European Makerfaire which opens this coming Friday 14th October in Rome.

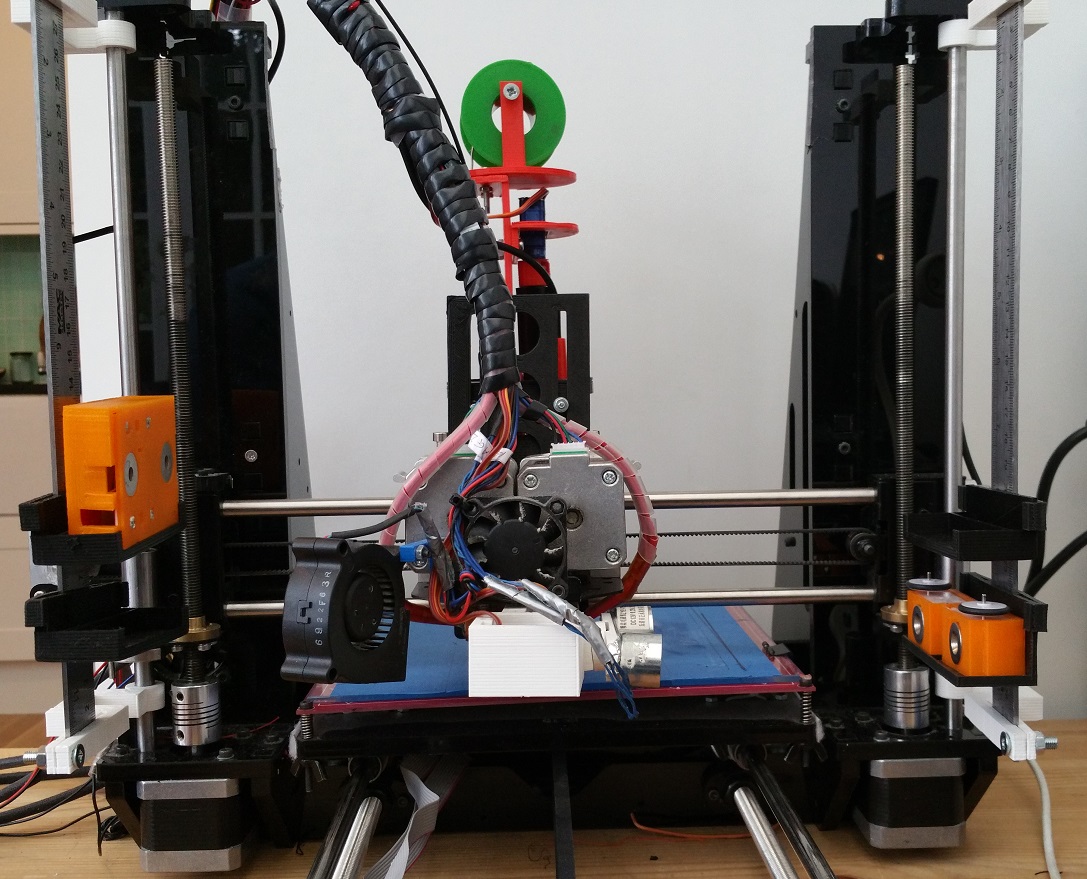

Using robotic assembly and low cost metal (non silver) circuit printing solutions, the technology is aimed at individuals and businesses that want to be part of a waste reducing, value adding product ecosystem. The system aims to create much more sophisticated, fully working products – similar to those that we buy in the shops today – using a combination of 3D printed parts and ‘standard modules’ containing non 3D printable items. The idea is that when people wanted a new product, they could take along one that they no longer wanted or needed to a local re-manufacturing hub or re- manufacture what they wanted themselves. This would involve opening up the old product by pulling it apart in special ‘weak zones’, recovering the modules and 3D printing the new product using these and other additional modules as required. The company have also been working on new forms of 2nd use packaging that is specifically designed to be used as components in a build to further reduce the time and cost of products. As products would be re-manufactured in tens rather than thousands, speed would also be less of an issue. One or more products could be produced overnight on a low cost prosumer machine.

Of course, designing, developing and delivering a product that is safe, reliable and desirable is not an easy task. For this reason, Buzz Technology have developed a FAIR SOURCE sharing economy platform that enables individuals and businesses with spare time, underused resources and capital to come together to develop killer products and share revenue.

Senake Atureliya, Buzz Technology’s CEO said: “Our solution is based around modules containing fully built assemblies such as micro controllers, PCs, displays, digital storage, motors, sensors and the like. As modern WiFi or bluetooth enabled micro controller can provide the functionality required by a myriad of different products, we didn’t see the immediate need to print PCBs and insert components like the two or three other players developing in this space.” He added “I have been involved with the design of factory and office automation solutions for years now. If we are to stave off the ‘robots taking our jobs’ threat, we need to put automation in the hands of the consumer so that they can produce more of the ‘food, warmth and shelter’ that they consume then educate and offer them the chance to build on these solutions. At Makerfaire Europe in Rome and Makerfaire Derby in the UK, we will be showcasing some of the solutions to help make this happen.”

As a first step, the retrofit kit for existing Prusa style 3D printers is available for pre-order on the company’s website in time for Christmas.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.