Cyfuse Biomedical K.K., a Japanese company that has developed the Regenova 3D Bioprinter, and Cell Applications Inc. have made their tissue-engineering services now availalbe to researchers in North America.

Cell Applications has created a service bioprinting model to create scaffold-free tissue using the Regenova printer and their new approach called the “Kenzan Method”.

“In addition to customized cell isolation and assay services, Cell Applications is now able to provide researchers with an integrated cell-engineering solution that utilizes our expansive primary cell bank and the innovative Kenzan bioprinting method,” said James Yu, Founder and CEO, Cell Applications. “Having the Regenova 3D Bio Printer at our San Diego headquarters with our vast array of primary cells is a powerful combination. We’re very pleased to offer researchers an end-to-end, customized solution for creating scaffold-free, 3D-engineered tissues that reduce costs by minimizing the lengthy processes typical in pharmaceutical drug discovery.”

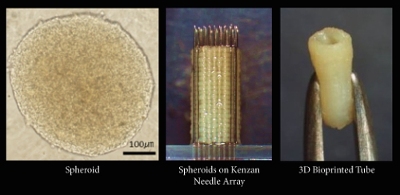

Unlike other bioprinters currently available, the Regenova does not depend on scaffolding made of biomaterials such a collagen or hydrogel to construct 3D tissue. Instead, the instrument assembles three-dimensional macroscopic tissue by forming aggregates of cells, called spheroids, one at a time and lancing them onto a fine needle array. Pre-programmed software guides the collection of the spheroids, which can then be designed and constructed into small spheres, rods, sheets, tubes or other tissue configurations. As the engineered tissue fully matures during culture in a bioreactor chamber, the individual spheroids fuse with one another into any desired pattern within a range of approximately 10x10x10 millimeter at 500um resolution. Multiple pieces of bioprinted tissue can then be integrated together to form even larger constructs.

Unlike other bioprinters currently available, the Regenova does not depend on scaffolding made of biomaterials such a collagen or hydrogel to construct 3D tissue. Instead, the instrument assembles three-dimensional macroscopic tissue by forming aggregates of cells, called spheroids, one at a time and lancing them onto a fine needle array. Pre-programmed software guides the collection of the spheroids, which can then be designed and constructed into small spheres, rods, sheets, tubes or other tissue configurations. As the engineered tissue fully matures during culture in a bioreactor chamber, the individual spheroids fuse with one another into any desired pattern within a range of approximately 10x10x10 millimeter at 500um resolution. Multiple pieces of bioprinted tissue can then be integrated together to form even larger constructs.

As the cells mature, they self-organize, promoting strong, reliable tissue that is further optimized by the design of the bio printer’s needle array that allows for optimum circulation of culture medium. The Kenzan Method, meaning “needle array” in Japanese, is a much gentler approach and greatly increases the percentage of viable cells that survive within the 3D construction, in contrast to bioprinting and scaffolding techniques that utilize high-velocity liquid flow which often damage cells and yield insufficient cell numbers.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.