Researchers at the ETH Zurich have developed a new technology for creating plastic models with different colours. With the new method all imaginable colours could be created – but there are also limitations.

The research was led by ETH Zurich professor Olga Sorkine-Hornung. The technique was developed by the doctoral student Christian Müller and Disney Research was also involved in the development. The new technique is especially suited for printing masks or small objects that consist of only a thin plastic layer. It is not suited for printing heavy parts that have to withstand high mechanical stress.

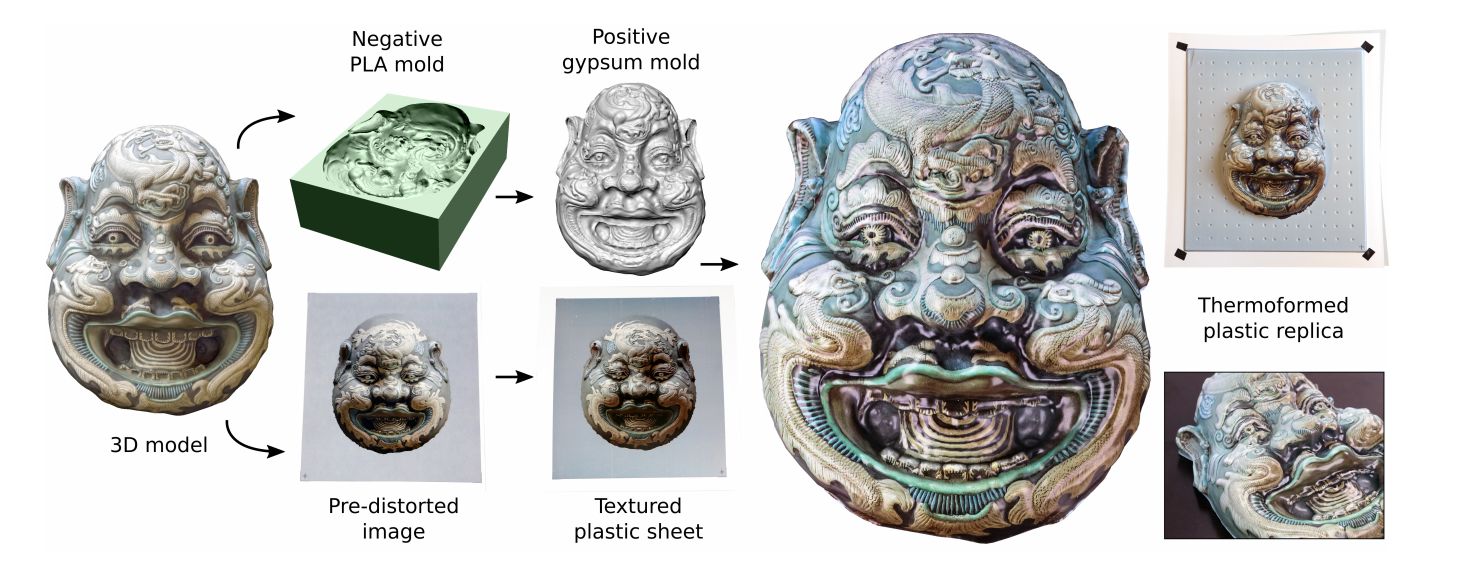

At the beginning a 3D model is created on a PC and is also coloured. Following, a negative form is created with a 3D printer that uses PLA as printing material. The form is then filled with a heat-resistant material before being melted away. Parallel to this process a program creates a texture out of the 3D model. This texture is printed onto a plastic sheet. In the last step the plastic is heated up and terraformed over the heat resistant model. This technique is also called Computational Thermoforming.

This detail is reproduced exactly in the copy. The surface has a high-quality look, and the colours and structure are almost identical to those of the original. The replica has a high quality appearance, and for many applications it’s cheaper and faster than today’s 3D colour printing process.

Of cause this technique has its limitations but there are cases where this technique is faster, easier to use and also cheaper as other 3D printing methods that can print with different colours.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.