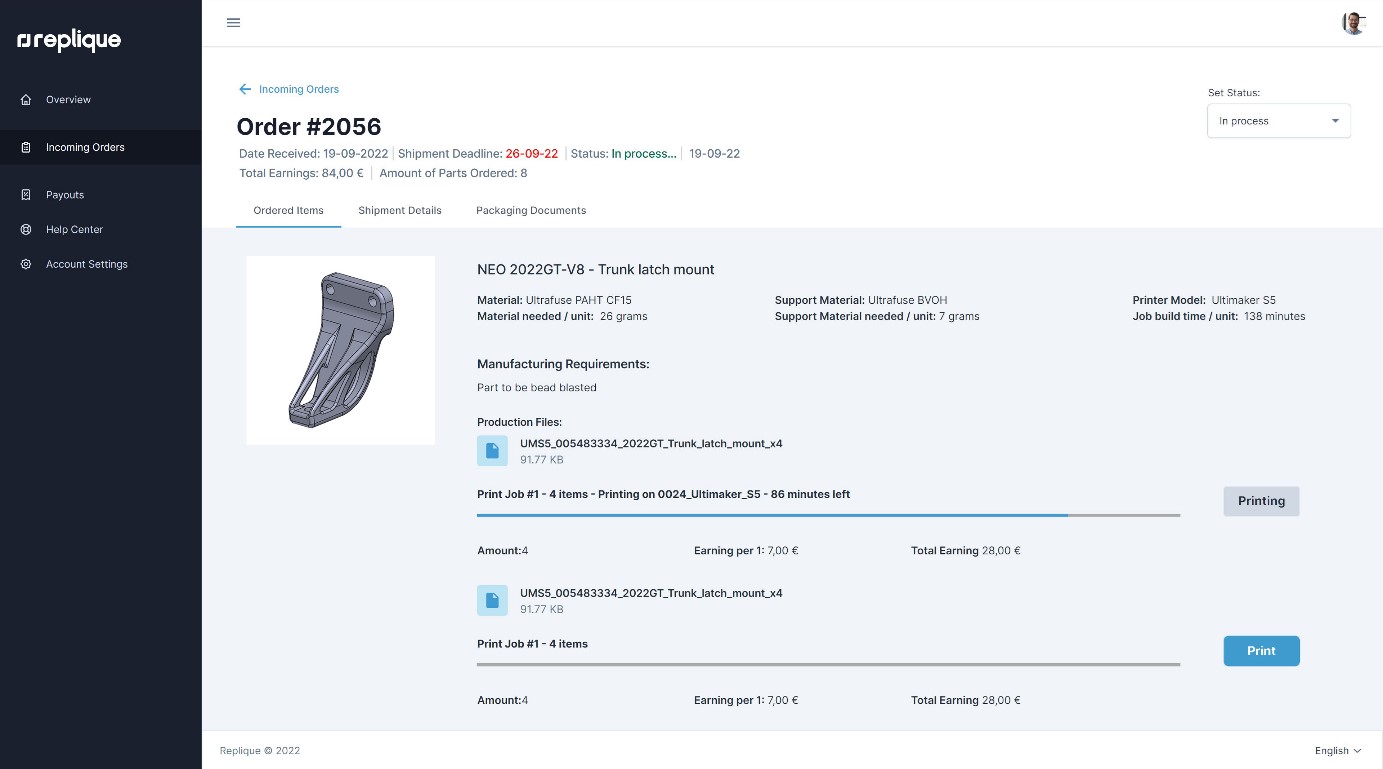

Replique, provider of a secure 3D printing platform that makes OEMs’ parts management more efficient and sustainable, is using Formnext to launch RSure, an innovative quality tracking module that enables OEMs to directly track each of their 3D-printed parts and ensure they meet required quality specifications. With RSure, OEMs can establish quality specifications and a digital inspection process, and track parts produced with Replique before they are shipped to customers. The new module will be introduced as part of Replique’s industrial 3D printing platform (Booth B73, Hall 12.1).

RSure also allows OEMs to determine quality checks that need to be performed by service bureaus on 3D-printed parts, including various certified measurements, functional testing and uploading images to the OEM’s digital library on Replique. Through the secure platform, OEMs can remotely access and view this information at any time.

Formnext visitors can test Replique’s encrypted ordering process – which ensures parts are printed in the desired quantity and quality – by ordering a free 3D-printed giveaway that will be produced at the booth. This also provides a close look at the company’s digital warehouse, which allows parts to be stored, managed and ordered internally.

In addition, visitors can learn about various use cases from Repliques customers. These include a project with Alstom that used a doorstop as the first 3D-printed production metal part for rail vehicles. It was qualified with Forward AM, brand of BASF 3D Printing Solutions GmbH, and mass produced using Ultrafuse 316L metal filament.

Max Siebert, co-founder and CEO of Replique, comments, “As part of BASF, we know that industrial companies need standardized and repeatable production processes, especially when it comes to distributed manufacturing. With our end-to-end solution, we can ensure part traceability while providing repeatable quality and secure encryption of 3D printed parts.”

Replique’s solution works for both B2B and B2C companies, and the use cases presented at Formnext cover only a small portion of potential application areas. In particular, the collaboration with

H. Gautzsch group of companies shows the diverse possibilities of the Replique platform for internal and external (customer-side) order processing, as does the project with premium home appliance manufacturer Miele.

Visitors who would like to make an appointment with Replique in advance of Formnext can contact Arash Rashidi arash.rashidi@replique.io.

Find out more aobut Replique at replique.io.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.