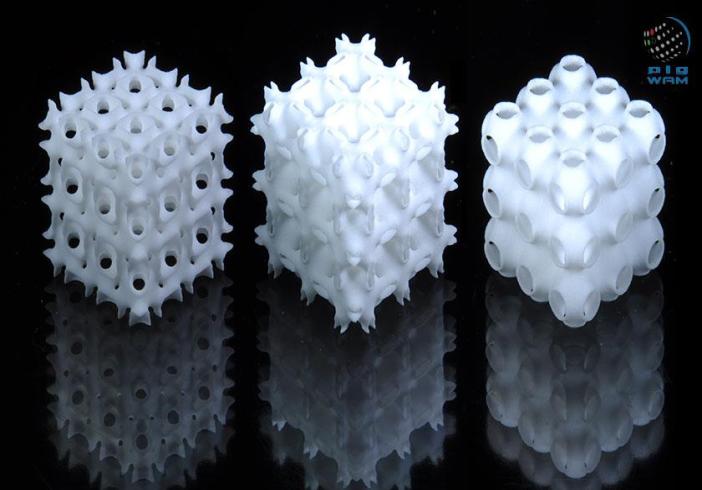

Researchers at the Masdar Institute of Science and Technology in Abu Dhabi have created strong lightweight architectured foam structures using 3D printing technology. These foam structures could potentially be used to make vehicle bodies much lighter and stronger as well as improve water production and oil and gas operations.

Materials including metals, plastics, ceramics and composite materials can be used to 3D print these foams, enhancing the thermal, electrical and mechanical properties of engineering systems or structural components.

Dr. Steve Griffiths, Vice President for Research at the Masdar Institute, explains:“The foam structures have the potential to become a platform technology, driving innovations across key industries and markets. This project demonstrates how Masdar Institute’s strong advanced materials research capabilities support disruptive technology-based innovations in the Institute’s core research areas of water and energy while benefiting other sectors of importance to the UAE.”

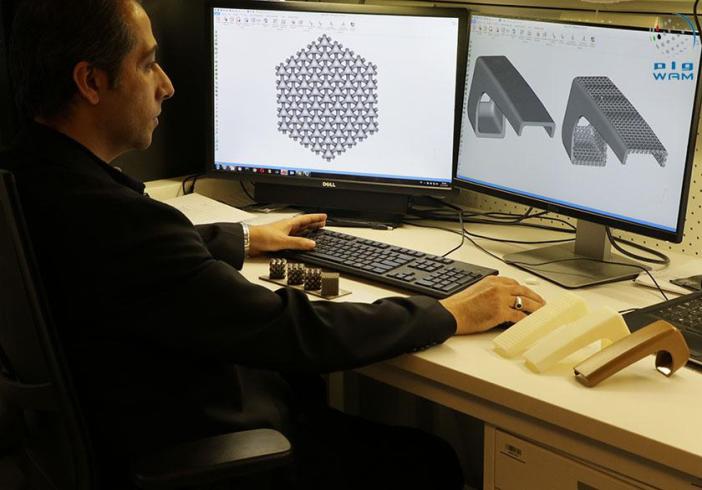

Through the collaborative research project, a computer model to design thousands of different foam structures has been developed, as key to their strength and light weight is the internal geometry. The computer model allows selecting desired properties of the foam, including thermal and electrical properties, weight and stiffness. Once generated they can be produced using a 3D printer.

“We have introduced a paradigm shift in how materials are being designed. Currently, people design materials based on a material’s existing chemistry, structure and its corresponding properties. Our vision for material design instead looks first at the desired properties you are targeting in a material for a product application and then applies our proprietary design methods to optimise the structure and its’ internal geometry so that it will give you those desired properties,” said Dr. Abu Al-Rub, Associate Professor of Mechanical and Materials Engineering.

In order to accelerate the commercialisation, the researchers are cooperating with several companies to secure funding for the proof-of-concept. As a next step the Institute is looking for UAE companies in the industry to collaborate and explore possible applications of the foams.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.