Researchers at King’s College London have successfully created a prosthetic chest for cancer patients using custom software and a 3D printer.

The case report, published in Frontiers in Surgery by researchers from the School of Biomedical & Imaging Sciences in collaboration with surgeons from Guy’s and St Thomas’ NHS Foundation Trust, shows the postoperative success of the procedure which leaves patients cancer free and with better quality of life.

When a patient has a cancerous tumour in the chest wall which protects the heart and lungs, the tumour needs to be removed. Surgeons will often need to remove part of the chest wall to make sure they excise all of the cancerous bone and tissue.

But the process can be expensive. Currently, costs exceed £10,000, which include the cost of the titanium implant (£1000+).

In contrast, the 3D printed mould method, developed by researchers Ms Antonia Pontiki and Professor Kawal Rhode from King’s, costs around £40 per unit.

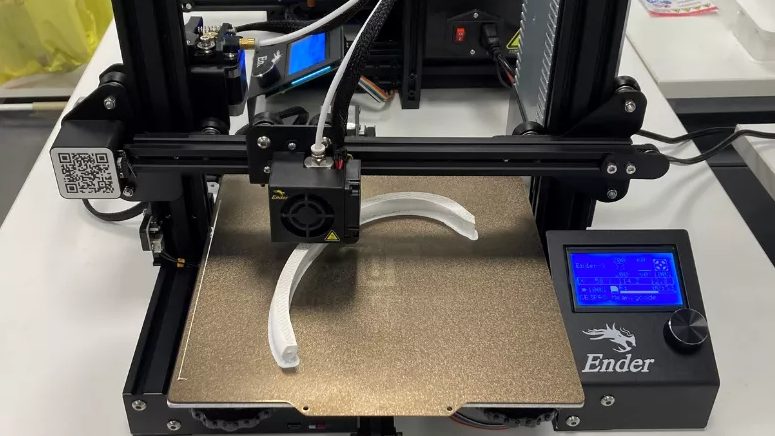

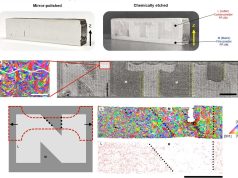

Thanks to the novel software, researchers can enter each patient’s characteristics (age, weight, height, sex, as well as the number and side of the ribs needing to be replaced) to create a digital version of the rib, ready to be 3D printed.

Once the 3D print is ready, a process which takes six hours, it is placed in a box of liquid silicone to create the mould. This is then sterilised and taken to theatre and filled with Polymethyl Methacrylate (PMMA), known as bone cement, and placed inside the patient. This process takes less time, uses less staff resources, and has better outcomes than traditional titanium protheses. The replacement is also more flexible than titanium prothesis and better mimics the suppleness of the ribcage.

“Our study was the first that proposes the use of this methodology in a clinical setting. By reducing the level of expertise and time required to build the prosthesis, the 3D printing and software technique could increase productivity and make this method more accessible in a clinical setting”, says Antonia Pontiki, a PhD student from King’s

Mr Andrea Bille, consultant thoracic surgeon at Guy’s and St Thomas’ comments: “The technique is extremely efficient, and the 3D reconstruction is reliable and effective for the patients, offering them a personalised model with reduced cost considering that we use a well-known material. The procedure to create the prosthesis is quick and efficient and considering the low cost, high quality and low comorbidity this should be endorsed by other hospitals and surgeons.”

Professor Rhode’s research team are now working on developing a low-cost 3D printer to allow for the part of the anatomy to be 3D-printed directly.

Find out more about the King’s College London at kcl.ac.uk.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.