In a scientific paper published in ChemElectroChem, engineers from Belgium and Germany successfully demonstrated the fabrication and testing of a titanium slurry electrode, proving that it is a viable means of increasing peak current density compared to conventionally manufactured solutions.

In slurry electrodes, complex flow distributors are used to enhance charge transfer between the current collector and the slurry particles. Subsequent heat treatment of the electrodes dramatically improves the anodic and cathodic current peaks.

Conventionally, these types of electrodes are used in electrochemical systems, such as fuel cells, batteries and electroplating processes. Now, the team has set its sights on fabricating a vanadium redox flow battery (VRFB) as applications.

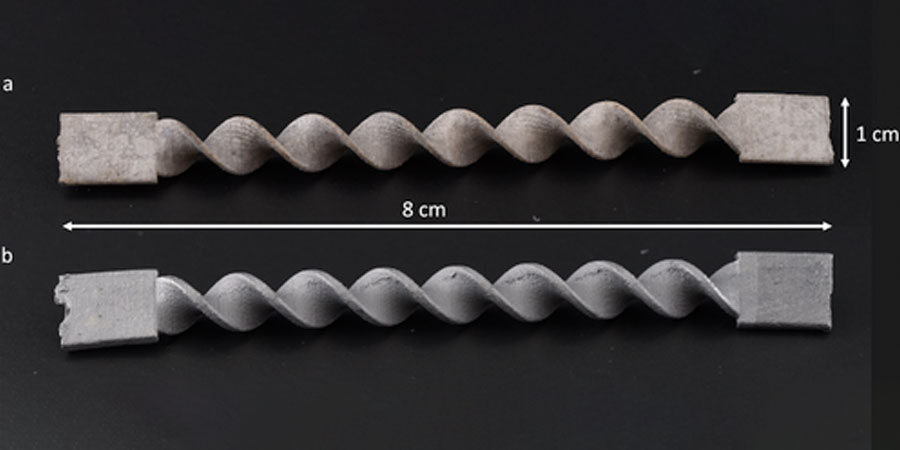

3D printing helped the team, consisting of researchers from the DWI Leibniz Institute for Interactive Materials, the University of Antwerp and RWTH Aachen University, create the flow manifolds for use in the VRF and fabricate a twisted geometry.

Slurry electrodes and 3D printing

Different oxidation states give the VRFB its ability to store energy. Common materials for the electrodes ssare paper or carbon-based felt. The team replaced these with slurry electrodes, which were integrated into the battery’s flow channels using 3D-printed static mixers (SMs). This allowed them to improve charge transfer between the collector and the slurry particles.

Once the static mixers were molded and printed, a paste consisting of titanium powder, epoxy, and glycerin was poured in. After the drying time, the mold only needed to be dissolved.

Since the mixer was now not yet conductive, a two-step process was used that simultaneously removed the binder.

Integration and tests

Some tests and analysis showed that up to seven layers of graphite could be sprayed on before delamination and surface deformation occurred. In addition, the TiSM electrode has up to three times higher peak current density in the positive electrolyte, but only up to two times higher peak current density in the negative electrolyte.

These results lead to the conclusion that a static mixer with slurry electrodes can improve charge transfer. These findings could therefore also represent an important step in the development of rechargeable batteries with this mode of operation.

The full study can be found here.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.