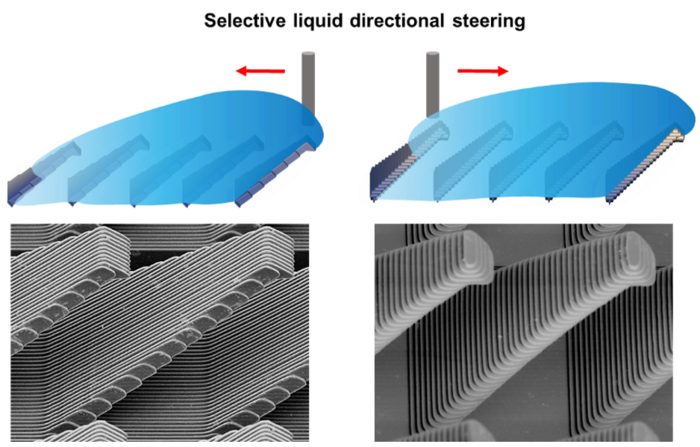

Conventional belief holds that the direction of dispersion of fluids with different properties depends on the design of the surfaces and cannot be adjusted. However, a recent paper published in Science has shown that it is possible to make fluids with different surface tensions choose their propagation direction on the same surface, which consists of 3D Macro Ratchets with double indented curvature.

Fabrication of these structures requires 3D printing and polishing treatments, which is complex and impractical for practical applications. A study in the International Journal of Extreme Manufacturing shows how to simplify these processes while maintaining fluid steering.

“It provides a new design of surface that is easy to fabricate or replicate, without sacrificing the function of liquids directional steering,” said Zuankai Wang, a chair professor in the Department of Mechanic Engineering at The Hong Kong Polytechnic University and the corresponding author of the study. “Essentially, it suggests new possibilities for making use of the often overlooked or useless part of materials to realize desired function,” said Jing Sun (postdoc at City University of Hong Kong), the first author of the paper.

The study breaks with a more than 200-year-old notion that fluids are always transported in directions that reduce surface energy. The researchers discovered that fluids can even spread in opposite directions on a special 3D ratchet.

The research doesn’t end there.

“We are curious how and to what extent can the second-tier microgroove structures rectify the spreading dynamics of liquids, so we prepared ratchets with microgrooves arranged along different orientations,” said Jing Sun.

The experiments showed that the orientation of the microgrooves indeed plays a dominant role in regulating liquids with moderate wettability, and that liquids can even spread in opposite directions on ratchets whose microgrooves are oriented perpendicular and parallel to the ratchet’s tilting direction.

“Microgrooves arranged perpendicular to the ratchet-tilting direction serve as delay valve to slow down the spreading of liquids on the side surface of ratchets, whereas microgrooves parallel to the ratchet-tilting direction would promote the spreading of liquids due to capillary wicking, thus the latter is more beneficial for the backward spreading of liquids.” said Wang.

The team continues to research the mechanisms of fluid-solid interaction.

“What we know is just the tip of the iceberg, more advanced visualization tools may be employed to reveal how the liquid and solid structures interact in the microscale, or we can even introduce other functions by adding different ingredients to the materials,” said Prof. Wang.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.