Researchers at the Tissue Factory at Utrecht University Medical Center have developed a hydrogel for 3D bioprinting, that they recently used to create a rabbit shoulder implant.

The hydrogels the research team around bioprocessing biologist Jos Malda have developed are firmer and more elastic than most cell carriers used as scaffolds. Malda believes that this will eventually allow them to restore larger parts of a joint. So far, these hydrogels have been tested with stem cells and cartilage cells.

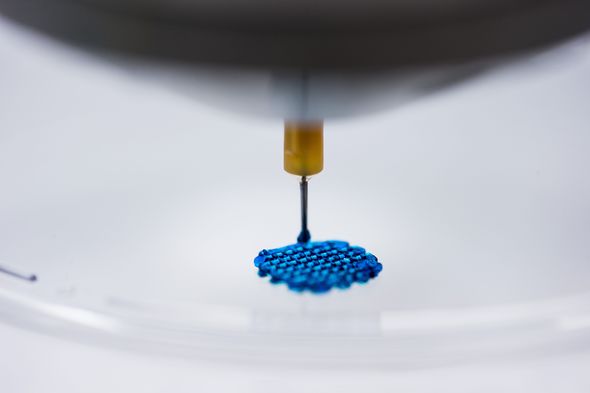

In order to enhance its strength and therefore be able to support the human body, researchers have combined it with other materials. They 3D printed it onto a framework of thin and thick fibres. Thicker fibres make the hydrogel structures strong enough for bone implants, while thinner ones maintain the flexibility of the structure and can be used for cartilage.

The researchers have recently 3D printed an entire shoulder that was implanted into a rabbit, with results to be evaluated over the next few months.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.