This year the company plan to support large corporations in adopting its advanced 3d printing technology to digitize short run manufacturing. With its innovative beltless mechanical movement system that offer new standards in accuracy and repeatability, and its unique offering of techno-polymers for metal replacement applications, the company aim to offer heavy industries a solution to serve their vision of transforming manufacturing into a more flexible, efficient and profitable process.

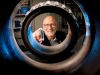

Bari, ITALY – 05th January 2017 – continues the march of Roboze, Italian manufacturer of professional 3D printing solutions for rapid prototyping and additive manufacturing applications, known for its innovations in the field of mechanical precision and for its offer of high-performance materials such as PEEK and PEI. The Roboze solutions meet a growing favor of audiences around the world with a significant growth in its business and a large expansion of its distribution channel.

This growth is a result of a large unsatisfied demand tank that begins to arrive on the market for the progress of a good awareness by companies and professionals from around the world of the advantages and capabilities that the 3D printing technology has to offer. The forecasts for 2017 and 2018 are in fact positive and demand it will also be supported by new technological innovations. The new products will continue to play a very important role in the march to the market.

Roboze, the manufacturer of the only 3d printer with a Beltless System, launched during the second half of 2016, its Roboze One+400, which was boosted thanks strategic partnership during the year, dedicated to aerospace, motorcycle racing companies, research lab, automotive and engineers.

A number of customers, from Formula One to Aviation, testified to the advantages of Roboze’s 3d printers, keeping significant results in terms of high-performance materials and accuracy. In view of global growth, the company certainly will not spare their weapons to consolidate its market position.

“2017 will be for us a very important year, the year of reaching out to leading global industries offering them unique solutions for the production of short serious end use parts, with a focus on metal replacement applications. Besides an increase in our infrastructures, the team and our distribution channels, we will focus on the quality of our products and services, research and innovation and diversification. We wish to be closer to the real needs of our market, especially the ones of professional users who seeks accessible solutions for advanced applications around additive manufacturing. “ says Alessio Lorusso, Roboze CEO.

Roboze, after an extensive coverage of EMEA, plans to complete soon the opening of its American branch to gain access to the NA region. It will be interesting to follow the strategic developments and the future products innovations of this company, and to follow up the acceleration of its global growth and expansion.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.