Roboze One+400 is a powerful industrial 3D printer that offer the use of advanced thermoplastics materials for additive manufacturing applications.

The Roboze One+400 presents two new unique features:

Beltless mechanical movement system – a patented mechatronic movement system that involves the total removal of the drive belts in favor of simple and effective traditional mechanical, as the combination of rack and pinion. The result is the ability to produce precise and high quality parts.

Accessibility to high-end thermoplastic materials – the Roboze One+400 owes its name to a pair of new extruders, designed and internally produced by the company, able of reaching a temperature of 400 ° C and which, together with other small innovations inside the machine, allows printing of 12 different types of high-performance thermoplastic materials such as PEEK, PEI and CARBON PA (Nylon12 filled with Carbon fiber). In specific two materials: PEEK and PEI that are available today only is high cost production 3D printers.

Roboze PEEK – What you need to know

It is a semi-crystalline thermoplastic polymer technologically advanced, as it combines excellent mechanical properties and excellent chemical resistance to a range of extraordinarily broad operating conditions, ranging from -60 ° C to 260 ° C, both in air, dry or wet, both in immersion.

The main features are:

- high mechanical strength, stiffness and hardness

- excellent dimensional stability

- fire resistance to self-extinguishing

- the very low flue gas density

- resistant to high and low temperatures

- excellent abrasion and wear resistance

- good balance between stiffness, strength and toughness

- low coefficient of linear expansion

The best application suites to perform are:

Additive manufacturing/Metal replacement applications: in which PEEK is popular in the following industries: aerospace, automotive, defense & military.

PEEK for medical applications. The mechanical, thermal and chemical properties of PEEK and the fact it can be approve as a biocompatible material makes it an excellent solution for medical applications and devices, especially for pre-designed gigs and surgery tools. As developers also of new materials, thanks to national and international scientific partnership, we are close to completing the Peek with medical grade which initially will allow the printing of surgical guides certified for contact with mucous membranes, blood etc … Roboze goal for the future in this field is to create a solution for implantable parts in the human body. Stay tuned!

By enabling the use of advanced materials, Roboze offers users a powerful yet affordable solution, together with the advantages of an ‘easy-to-use’ desktop 3D printer. This will open up a wide range of new possibilities, especially for SME’s for a variety of applications in several different industries requiring only a limited amount of investments.

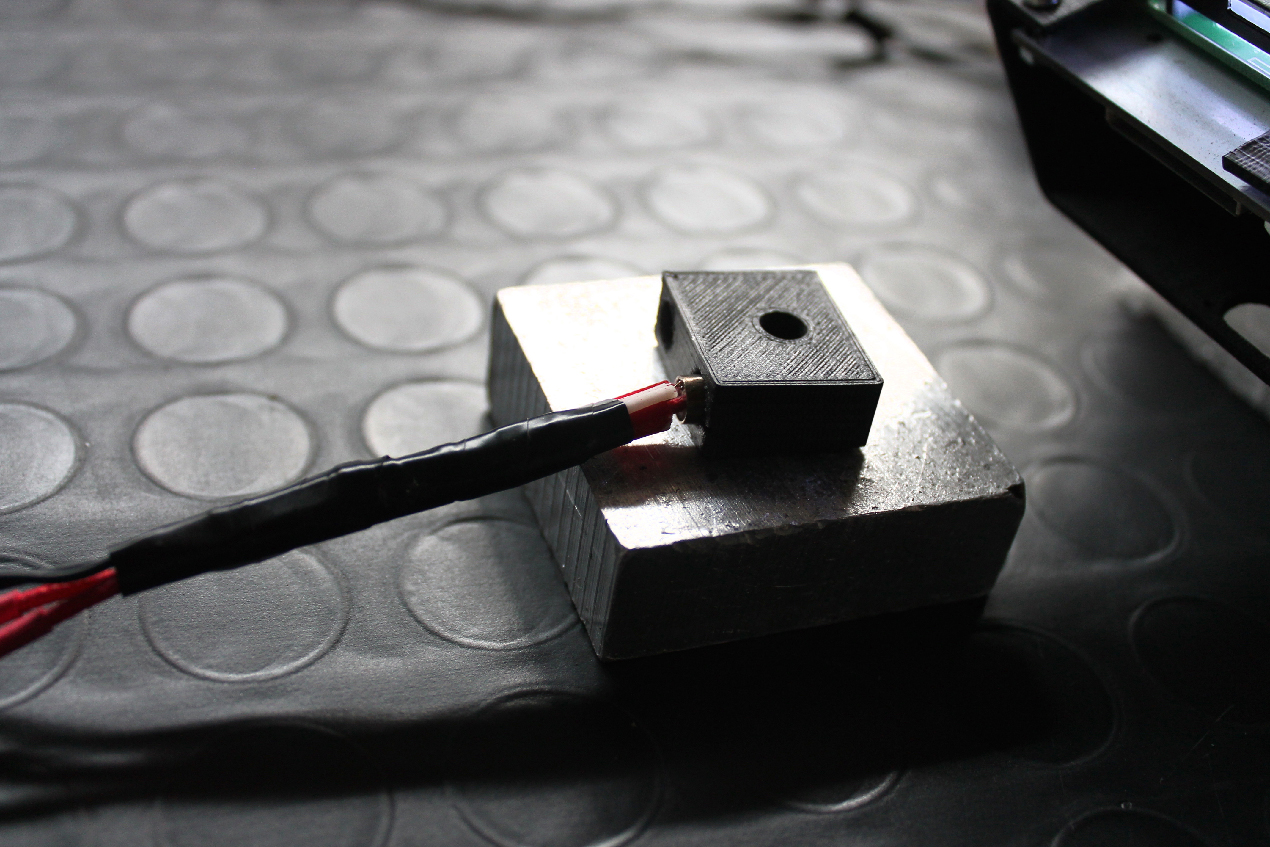

Next week, we at Roboze, will publish a test video that will show one of the best performance of PEEK: the Thermal Inertia of Roboze PEEK.

For further information please fill in the form. Be part of the change!

Below a little preview:

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.