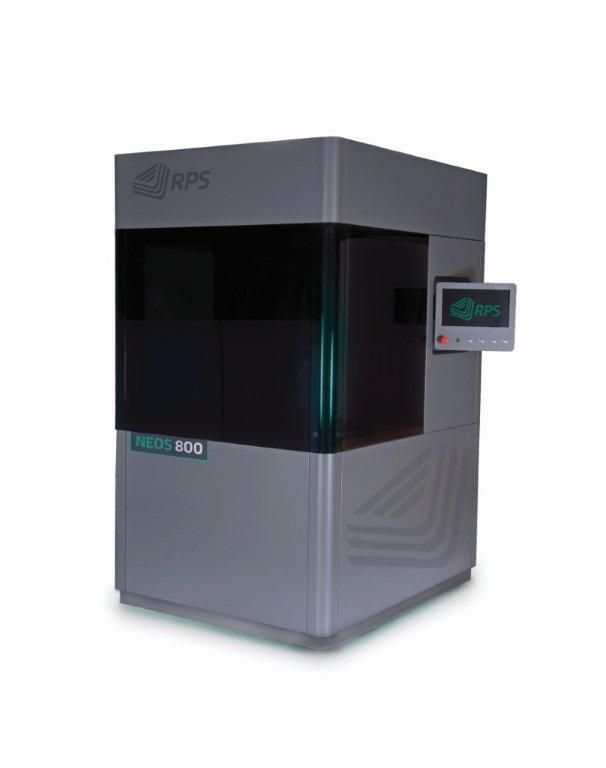

RPS is very pleased to announce the launch of their new professional stereolithography system, designed, developed and manufactured by RPS engineers in the UK.

The first stereolithography system in the range is the NEOS 800, offering a large 800 x 800 x 600 mm build envelope designed to meet the requirements of modern digital manufacturing. The NEOS 800 can also be supplied with medium 300 mm or short 120 mm vats, sleeved into the standard full vats. The NEOS 800 features an open resin system, which allows the use of current commercial materials designed to cure at a wavelength of 355 nm and will facilitate the development of further functional materials. The NEOS 800 employs a 2 watt solid state frequency tripled Nd:YVO4 laser, at 355 mm which will also allow the system to process highly filled materials requiring high laser powers.

The NEOS 800 has proven itself in a manufacturing environment, producing highly accurate, detailed parts of outstanding quality, with a scanning resolution to within 1 micron. It has an overall machine size of 1350 (w) x 1630 (d) x 2300 (h) mm and with a full vat of resin weighs approximately 1,590 kg.

The new stereolithography system has been designed by RPS engineers, whose combined experience in 3D printing of 85 years, has been utilised to produce a serviceable product. One of the key design objectives was to produce a stable high power system capable of delivering exceptional sidewall quality in order to reduce post-processing and part finishing times and thus part cost. Superior components have been carefully selected to achieve a robust reliable system capable of continuous production at high scan speeds. Easy to clean recoater blades, a modular design and an in-built webcam all contribute towards this unique quality system, designed and manufactured here in the UK.

The software, Titanium, also designed and built by RPS engineers, is designed to work with Windows 10 and takes many of its themes from the easy-to-use tiled display of the Microsoft operating system. The workflow is logical and the user is able to change the build parameters while the machine is building. Email notifications of the build progress are sent along with a photograph of the 3D print once the job is complete.

The new NEOS 800 system will be launched and on show to visitors on the RPS stand C18, at the TCT Show 2016, NEC, Birmingham on 28 – 29 September. Sample parts built on the new hardware will be available and RPS invites you to stop by and take a look at the NEOS 800 stereolithography system on display.

“This is an exceptionally well engineered system, designed and developed by people who understand the product”, commented David Storey, Executive Director at RPS. “It has a truly open resin system that is adaptable to meet different customer’s resin requirements, and we are very pleased to be launching it at this year’s TCT Show in September.”

“We are very proud of our knowledge, experience and reputation at RPS, and to have such a brilliant team of people, who have shown their capabilities in designing this exciting new product”, said Steve Moran, Director, at RPS. “We truly believe we can drive stereolithography technology further and provide manufacturers with hardware solutions to meet their future manufacturing challenges.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.