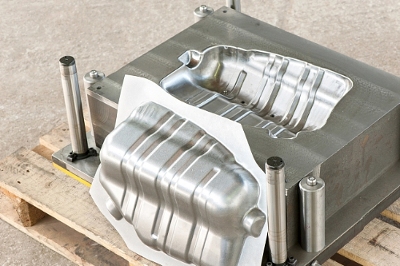

Sciaky, Inc., a subsidiary of Phillips Service Industries, Inc. (PSI), and provider of metal 3D printing solutions, announced today that its Electron Beam Additive Manufacturing (EBAM™) technology helped a major automotive manufacturer cut significant time and costs with the creation and repair of several tooling and stamping dies.

The manufacturer leveraged Sciaky’s EBAM to deposit complicated tooling features, as well as perform customized repairs and cladding operations for several high-volume parts. After a successful proof of concept (POC) engagement, the 3D printed tool was put into production.

“Sciaky’s EBAM technology is not limited to titanium parts and aerospace applications,” said Bob Phillips, Vice President of Phillips Service Industries, Inc. “We have provided 3D printed solutions to customers in a variety of industries like automotive, agricultural, defense, nuclear, oil & gas, and sea exploration using a wide variety of metals like stainless steel, tantalum, tungsten, Inconel, and niobium.”

In July 2016, EWI, a leading North American engineering and technology organization dedicated to developing, testing, and implementing advanced manufacturing technologies, purchased an EBAM system to produce prototype parts for high-tech manufacturers in a variety of industries across the U.S. Sciaky and EWI will work together to co-market their extensive metal 3D printing capabilities to the marketplace.

As the most widely scalable, metal 3D printing solution in the industry (in terms of work envelope), Sciaky’s EBAM systems can produce parts ranging from 8 inches (203 mm) to 19 feet (5.79 meters) in length, but can also manufacture smaller and larger parts, depending on the application. EBAM is also the fastest deposition process in the metal additive manufacturing market, with gross deposition rates ranging from 7 to 20 lbs. (3.18 to 9.07 kg) of metal per hour. Plus, with a dual wirefeed option, two different metal alloys can be combined into a single melt pool to create “custom alloy” parts or ingots. In addition, the mixture ratio of the two materials can be changed to create “graded” parts or structures.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.