Simplify3D has just released an update of their all-in-one 3D printing software. Not only does this include a number of new features but the company has also expanded the 3D printer compatibility.

Simplify3D is an all-in-one software for you 3D printer to import and manipulate geometry, repair mesh problems, apply custom print settings and to slice files and generate G-Code instructions. Further you can watch an animated preview of the build sequence and manually control your 3D printer. The software also allows for 3D printing from a SD card or USB.

According to CEO and Founder Clayton Webster, they “currently support over 100 different 3D printers, and are constantly adding new models to that list.” He continues: With this release, we are pleased to add 19 new 3D printers to our Supported Printer List including the MakerBot 5th Generation, XYZprinting da Vinci and PowerSpec 3D printers.”

A list of all 3D printers supported by the software can be found here. Among the new features to help improve model quality and precision are the following:

Thin Wall Intelligent Fill – This feature gives you all the controls you need to avoid gaps in thin walled parts. Most FFF printers have a fixed nozzle size, which can be troublesome when you try to print smaller features of your models. However, the new intelligent fill algorithms in the Simplify3D Software will help detect these potential gaps so that they can be filled to create stronger, better looking parts.

Strong Thick Infill – This option allows you to increase the width of your infill to create a stronger internal structure without sacrificing print time. For example, using an infill width of 200% would allow your interior structures to be twice as thick as your perimeter outlines, which will significantly increase the strength of your parts. This is also helpful for extremely fast moving printers that may have otherwise created “wispy” infill patterns.

Variable Density Support Structures – A new option allows you vary the density of your support structures, placing denser material close to your model where you really need it. This is particularly helpful when you are using dissolvable filament for your supports. For example, you could specify low-density infill for the majority of your supports (20%) then increase density for the top 5 layers of your supports (70%), as shown in the green image. This results in the cleanest possible underside on your finished model, while also saving time and filament.

Improved Options For Dual-Extrusion Printing – this update also includes several changes to help improve dual extrusion printing. You can now control which extruder is used for your rafts, skirts, and brims. You can configure longer tool change retractions to help eliminate oozing while one tool head is idle. The interaction of rafts, skirts, and support structures between different processes has also been greatly improved so that you can enjoy all of the control that the Simplify3D Software offers, even when using multiple extruders!

Simplify3D has also gathered feedback from Users and added the most requested features.

The software is available for $ 140 on their website.

February 3, 2015: Update – Simplify3D now supports Dremel and Moment 3D printers

The latest release from Simplify3D expands the software’s compatibility and improves print quality for 3D printer brands all around the globe. The company has added support for the new Dremel Idea Builder 3D printer. Owners of a Dremel 3D printer can check out the Dremel Hardware Setup Guide.

The software company also recently finalised a partnership with the breakout Korean 3D printing company, Moment, adding integrated support for the Moment 3D printer directly into Simplify3D.

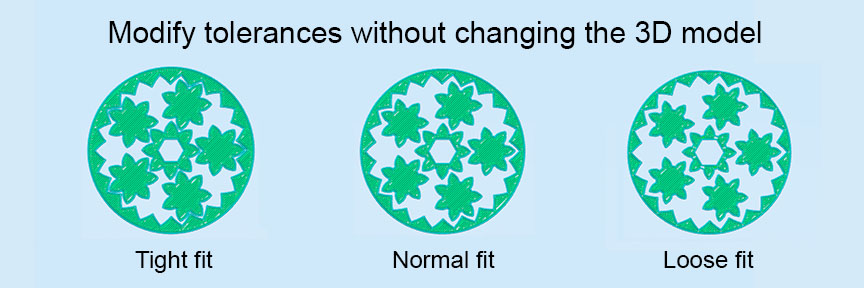

Users will also benefit from new features that improve print quality when fabricating objects with strict dimensional and tolerance needs. New options allow users to calibrate the spacing between inter-locking parts. For example, if you are printing a set of meshing gears or creating a series of bolt holes, the software provides precise control to modify these tolerances. With one click, you can change from a tight fit to a loose fit without changes to the original 3D model. This same feature also allows you to customize the outer dimensions of your 3D-printed parts, ensuring that the final model has the same measurements as your original design.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.