Solukon optimizes the SFM-AT1000-S for components made with SLM Solutions’ NXG XII 600 and presents it for the first time at Rapid + TCT in Chicago. The NXG XII 600 is revolutionizing volume production of beam-fused metal parts, especially large and heavy components. Solukon has adapted the SFM-AT1000-S depowdering system to the NXG XII 600 in collaboration with SLM Solutions.

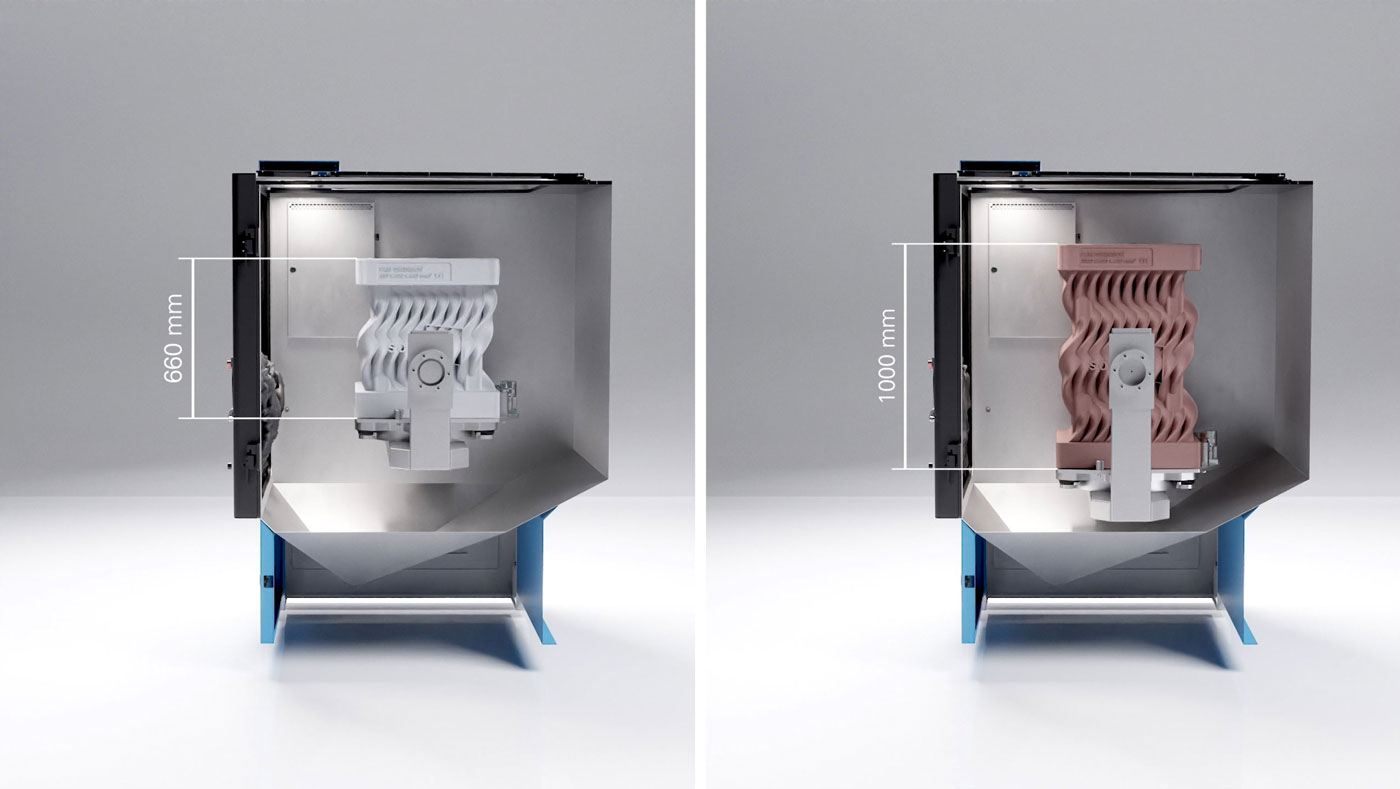

The new version offers an optimized, short swivel arm for a better center of gravity and easier access to the component. An optional front-roof loading enables easier part handling. When opening the roof, there is no need to “thread” the component from above, and the front door can be opened wider to facilitate loading and unloading.

The SFM-AT1000-S is based on SPR Smart Powder Recuperation technology and offers digital features that make it one of the smartest and best powder removal systems on the market for large components. The Digital Factory tool monitors the process, and the SPR Pathfinder software calculates the ideal motion sequence to remove powder from complex internal structures.

SLM Solutions has itself acquired a new-generation SFM-AT1000-S and is using it to reliably and quickly remove powder from NXG XII 600 components. The two companies are thus intensifying their long-standing partnership.

“The NXG XII 600 is the gold standard in industrial 3D printing. We are also collaborating with the market leader in the area of depowdering, and are glad that Solukon is launching a depowdering solution that fits our system perfectly,” says Sebastian Feist, Product Manager for Factory Integration & Periphery from SLM Solutions.

Andreas Hartmann, Solukon’s CEO/CTO, is certain that his company is equipped to meet the trend of increasingly large parts: “The NXG XII 600 from SLM Solutions has set the entire large printer market in motion. We are happy that we can now offer the numerous NXG XII 600 users a customized depowdering system as well. Even larger parts measuring 1,500 millimeters, produced on an NXG XII 600E for example, or more on the Z-axis will inevitably require Solukon automated depowdering solutions. We are in ongoing discussion with manufacturers to ensure that we can always provide the right system. The SFM-AT1000-S for NXG XII 600 will not be the last Solukon system for the large-format printers.”

Find out more about Solukon at solukon.de.

For more information about SLM Solutions, please visit slm-solutions.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.