Zurich-based software company spherene brings its ADMS technology to the public. At this year’s Formnext in November – considered the world’s largest meeting place for the professional scene around additive manufacturing –, spherene will present their latest development, which allows the benefits of ADMS technology to be applied to users’ models. Also, trial packs with three models to test the cutting-edge technology are now available for any 3D printer.

Last year, the spherene team was already part of Formnext, RAPID + TCT 2022 and other various industry-specific, international events and trade fairs in the field of additive manufacturing. Now, from November 15-18, the engineers will present their latest developments at Formnext in Frankfurt/Main, Booth 12.0 – B81N, thus furthering the company’s goal of advancing 3D printing and enabling a resource-conserving, energy-saving economy.

The future of additive manufacturing: Autonomous Design

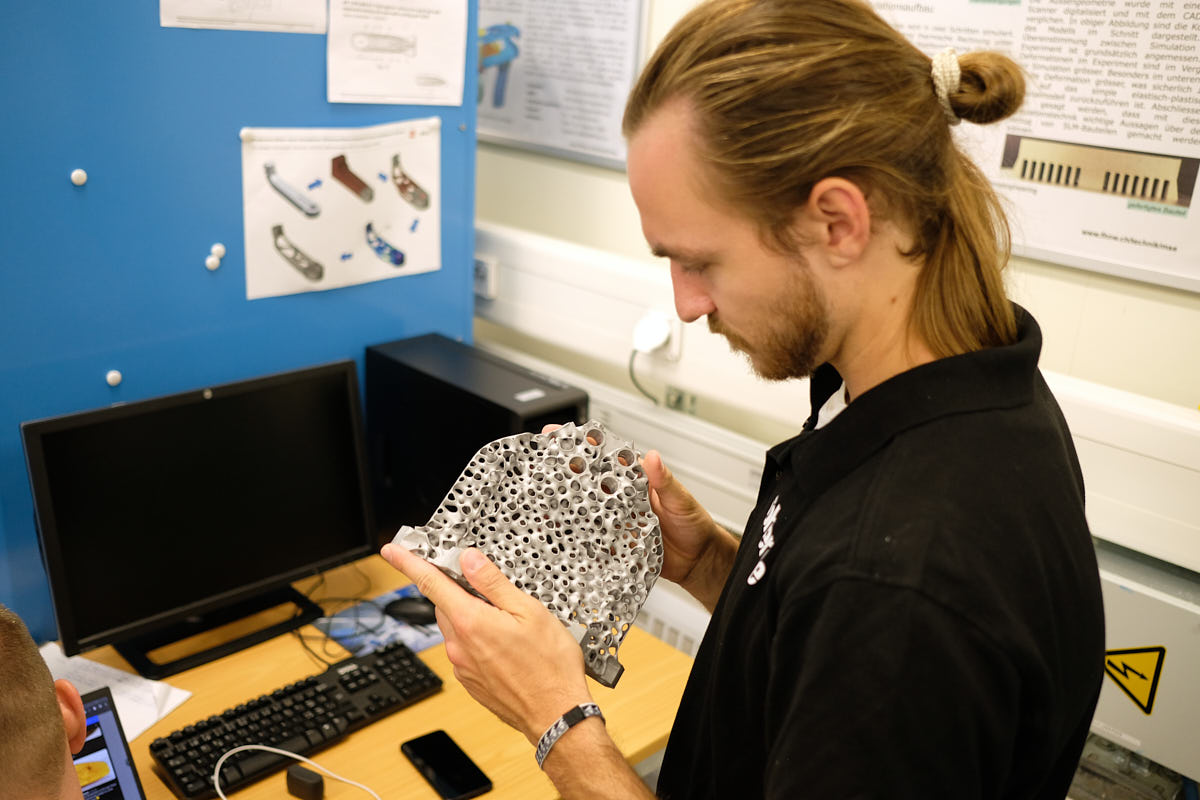

For a long while, technical difficulties, cost and time constraints were major obstacles, but with the rise of 3D printing, a new era in industrial manufacturing has begun. spherene’s software solutions start from there and tackle all these problems. Their proprietary technology is based on Adaptive Density Minimal Surfaces (ADMS), which are new kinds of minimal surfaces representing optimal geometry. They become accessible through spherene’s software and deliver reliable, repeatable and verifiable results. The ADMS technology belongs to the field of Autonomous Design, the algorithm-based design process that involves calculating the optimal geometry within set parameters. The spherene team is convinced that the precise outcomes, the designs with technical excellence, and the fast processing will revolutionize the industry.

Trial Packs

ADMS Technology to try out spherene is based on a strong maker spirit and therefore invites users to experience the benefits of ADMS technology for themselves. That’s why they have developed a trial package that includes three models that can be printed with any 3D printer. One of them has been created with sphereneMAKE, the upcoming software product that, as a web service for makers, automatically infills uploaded 3D meshes with the ADMS structure. Also the other models are created with the unique structure and profit from all its benefits: fine- walled, supported internal overhangs, and stable walls and tops. The package is available for download on the website.

Find out more about Spherene at spherene.ch.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.