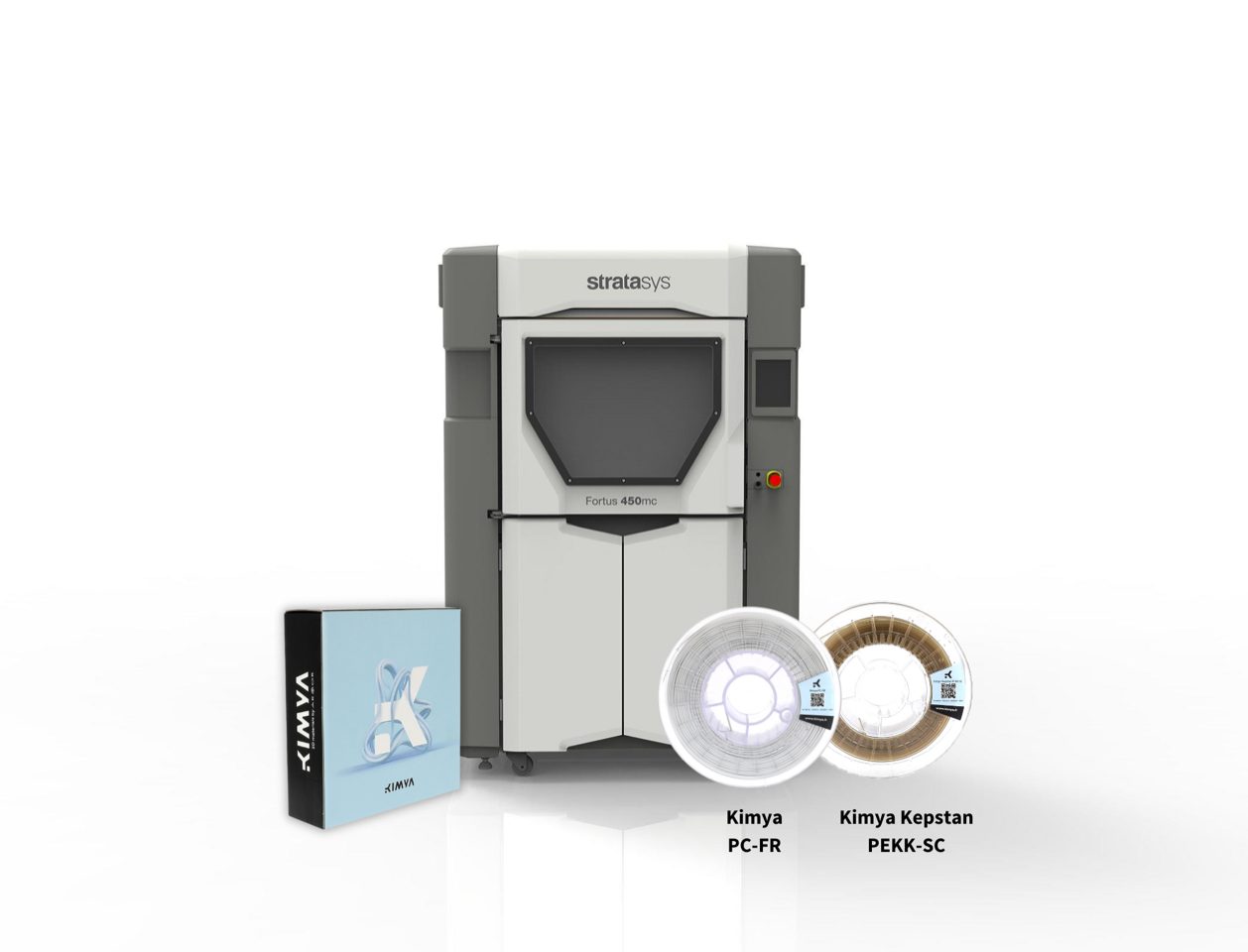

Stratasys, a global expert in polymer 3D printing solutions, has selected KIMYA, an ARMOR company, to provide Stratasys Validated materials for its FDM technology-based systems, which were previously closed to third-party filaments. With the integration of KIMYA into its ecosystem, Stratasys offers its customers a wider range of materials, greater flexibility, and the ability to accelerate the adoption of additive manufacturing into their production processes.

Both an expert in custom 3D material formulation and the production of finished parts with utility value, KIMYA now offers Stratasys’ industrial customers two new materials: EN45545–2 certified polycarbon filament (Kimya PC-FR) and a polyetherketone filament made from Arkema’s KEPSTAN (Kimya PEKK-SC). These two materials will be marketed from the second half of 2022 and will be used in particular in the rail and oil industries.

“We are expanding our ecosystem of materials to offer our customers a wide range of 3D

printing technologies and solutions, while ensuring our customers maintain the utmost

confidence in the performance of these filaments. That’s why we partner with excellent

companies like KIMYA, whose expertise in custom 3D material formulation includes the

production of finished parts with use value,” said Adam Pawloski, Vice President of

Manufacturing Solutions at Stratasys.

Accelerating the adoption of additive manufacturing

These initial materials begin what both companies say should be a long-term partnership

to accelerate the adoption of additive manufacturing at production scale. Stratasys and

KIMYA also initiated an R&D program with the goal to bring new co-branded filaments to

market by spring 2023. For example, KIMYA brings unique expertise in formulating

recycled 3D materials that could be applied to the collaboration. Additionally, through the

provision of a Stratasys Open Materials License, KIMYA will have the opportunity to work

directly on the printing parameters of Stratasys printers to develop new custom materials.

“We are delighted to see the expertise of KIMYA’s teams recognized by the world’s

leading polymer 3D printing solution provider. Together, we will be able to offer

manufacturers new innovative and high-performance materials capable of meeting an

ever-growing number of applications. This partnership reflects our common vision of the

market, which is to accelerate the transition of additive manufacturing to production scale

through the creation of a strong ecosystem. The partnership is the outlight of KIMYA’s

vision of the essential role of industry, and more specifically of 3D printing, in today’s

world: to produce just, without wasting resources, as close as possible to the needs of

the market” concludes Pierre-Antoine Pluvinage, Business Development Director at

KIMYA

More About: Stratasys, KIMYA and ARMOR.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.