Roboze’s Engineered PEEK material under Thermal Stress. Amazing Video

Bari, ITALY – 18 Lug 2016 – Roboze, world best Beltless FFF 3D printer manufacturers, has decided to conduct a thermal inertia test on the Roboze’s PEEK material.

The PEEK material is known as one of the best performing polymers in the world both in the mechanical and thermal point of view.

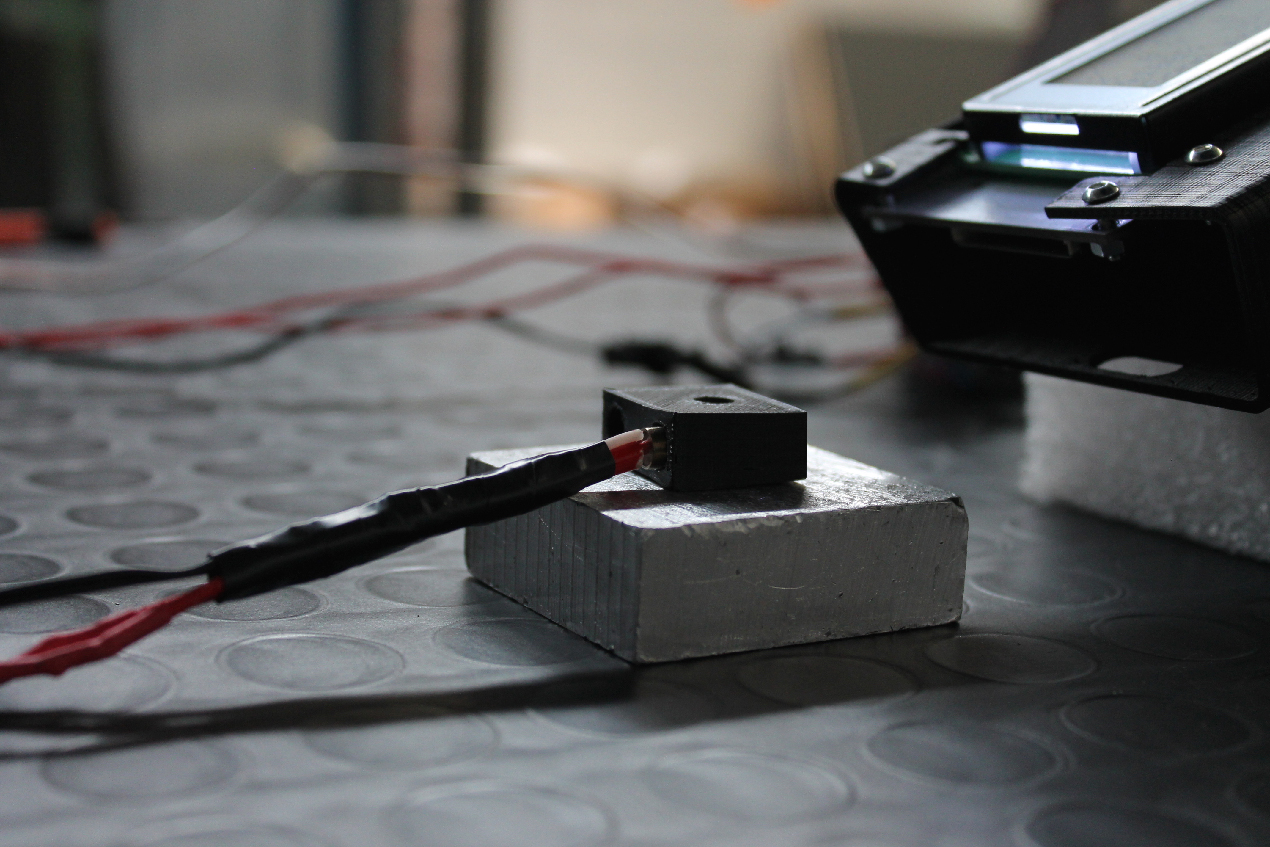

This test will be taken place to demonstrate how the Roboze’s PEEK material will react under stress of high continuous temperatures of 245o for an extended period of time and only losing 35% of its properties compared to the original standard conditions. Using the Roboze One+400 to print a 25 x 25 x 10 (mm) block, the PEEK material, is put in contact with a heated electric resistor at 245o at a high continuous temperature for 8 hours and 30 minutes.

This excellent thermal resistance and mechanical properties of PEEK makes it one of the most widely used polymers in various high shock applications and in prolonged heat resistance over time; used in applications such as: aerospace, defence, automotive, mechanical and aeronautic.

Roboze has once again broken the boundaries of the high-thermoplastic polymers. Thanks to the Roboze team, the company will keep striving and searching for new top quality materials and engineering revolutionizing solutions for the 3D-Printing world.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.