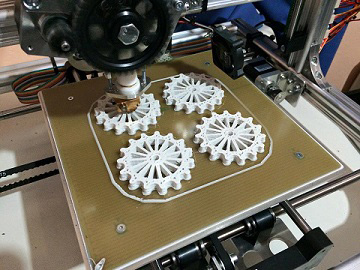

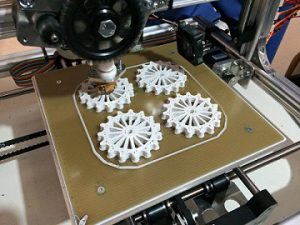

3D printing becomes popular nowadays and has been used in different industries such as in aerospace, automotive, medicine, architecture and many more. This also means that the possibility of printing models become almost endless.

3D printing becomes popular nowadays and has been used in different industries such as in aerospace, automotive, medicine, architecture and many more. This also means that the possibility of printing models become almost endless.

Since most people are now into 3D printing, it is important to research and learn more about this manufacturing method. Questions such as “Does 3D printing actually work?” or “Is 3d printing really worth the time and money?” may be asked.

Knowing the pros and cons of 3D printing can help manufacturers understand this process. Listed below are some advantages and disadvantages of 3D printing. Read on here.

Advantages of 3D printing

3D printing basically makes the manufacturing process less-hassle and efficient. Aside from these, there are also other benefits why some manufacturers use 3D printing for their prototypes.

Short turnaround

With 3D printing, printing time is relatively faster compared to the traditional one. With the help of rapid prototyping, designs can be printed quickly unlike the normal manufacturing process.

Able to customise and create complex designs

One of the most obvious advantages of 3D printing is the opportunity to customise designs. As long as the design is rendered on the computer, it is easy to create variety of items.

Furthermore, product designs are easier to evaluate and iterations can be done in the early stages of development. Dozens of duplications of an item can also be made. In this way, engineers can test its properties until the desired product goal is achieved.

Unlike the traditional methods of manufacturing, 3D printing allows engineers and designers to create models with complex parts and shapes. Also, it is now possible to create objects with interior cavities or unrealistic overhangs. There are no limitations when it comes to the geometries of the object.

Less waste

CNC machining has an extremely high amount of wastage. For example, a block of material may involve a lot of cutting throughout the process. This also means that huge amount of raw material is lost. However, since 3D printing is an additive process (the material is added layer by layer), only the required material is used to create a final object.

Easier to verify and test a design

With 3D printing, it is possible to verify and test a design before making large investments in mass production. In this way, it will also be easier to fix, revise or improve certain product features and functionality to achieve certain product goals.

Clearer representation of the design

With traditional manufacturing, it is very difficult to represent or deliver a certain design since the construction only leaves up to the imagination. Accordingly, a tangible prototype is easier to work on unlike a conceptual description or picture of a product.

Take architectural industry as an example. To better visualise architectural designs and models, it is best to use 3D printed objects. Likewise, 3D prototypes are printed in good quality to present the models effectively.

Disadvantages of Prototyping

Aside from the advantages of 3D printing, its disadvantages must also be considered carefully before deciding to implement them. Below are some of the cons:

Material Limitation

There are more than 100 3D printable materials that are available today, but the selection is still limited compared to the traditional method. Moreover, other materials such as concrete, conductive polymer, etc. are not widely used or still under development. Moreover, choices for surface finish is also limited to 3D printing.

Complex workflow that results in user confusion

Using 3D printing machines may be quite difficult for first timers. It is not as simple as printing a document in a paper from Google Docs where you simply click the “print” button and you’re all good. The general workflow of 3D printing may be confusing especially for beginners.

Aside from the basic steps of printing, they have to manually set up the equipment carefully or else issues will be encountered such as poor resolution, geometric inaccuracies, etc. It will take in-depth training and mastery to manage these complex machines.

Copyright infringements

Since 3D printing allows people to print almost anything, anyone with product blueprint can forge the items quickly. Counterfeiting products will become common and it will be almost difficult to identify the original one. It may also be challenging to protect the rights of the legal owners who manufacture unique products.

Harmful emissions

3D printers can generate potentially toxic emissions and carcinogenic particles. Based on a study, 3D desktop computers could emit a large amount of hazardous volatile organic compounds and harmful ultrafine particles. Using 3D printers in an enclosed place can pose health risks that include cancer and other serious diseases.

Materials can be very expensive

There are some materials that can be very expensive. For instance in metal 3D printing, a kilogram of titanium powder may cost up to $670. For a cheaper choice, nylon filaments are now available which costs up to $95 per kilogram. Note that this price range is just for the materials alone.

Conclusion

There are a lot of things that need to be considered before getting into 3D printing. Apart from the benefits that you can enjoy, it is still an evolving manufacturing process with some limitations that need to be considered. Depending on the complexity of the project, it is up to the manufacturer to decide if it is the best process to use for their prototypes.

If you find 3D printing beneficial and effective for your project, then you can start outsourcing to a 3D printing company that provides services that will suit your needs

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.