Imperial startup TOffeeAM has secured £5 million in international venture capital investment, money that will support further growth in its business applying artificial intelligence (AI) to the design of greener, cleaner engines and other machines. It already counts big names such as Boeing and Rolls-Royce among its clients, along with several Formula 1 racing car teams.

“We are delighted to have received this investment from our funding partners, both new and old,” said Professor Francesco Montomoli of the Department of Aeronautics, who is co-founder of the company and its chief executive. “This funding will give TOffeeAM the opportunity to scale globally and continue to help businesses across numerous industries to design innovative products.”

“TOffeeAM’s understanding of the customer and technology is testament to the exciting innovations emerging from UK universities”, commented Daniel Carew, IQ Capital.

The Series A investment round was an international affair, led by Presidio Ventures, part of the Japanese multinational Sumitomo Group, and London-based venture capital investor East Innovate. UK deep-tech investor IQ Capital, which led TOffeeAM’s seed round, also participated, along with Exor Seed from the Netherlands, US venture fund Type One Ventures, Italian investor Excellis, and several veteran angel investors.

“From our initial investment back in 2019, we recognised the potential in TOffeeAM’s team and technology,” said Daniel Carew, Principal at IQ Capital. “Their understanding of both the end customer and technology is testament to the exciting innovations emerging from UK universities.”

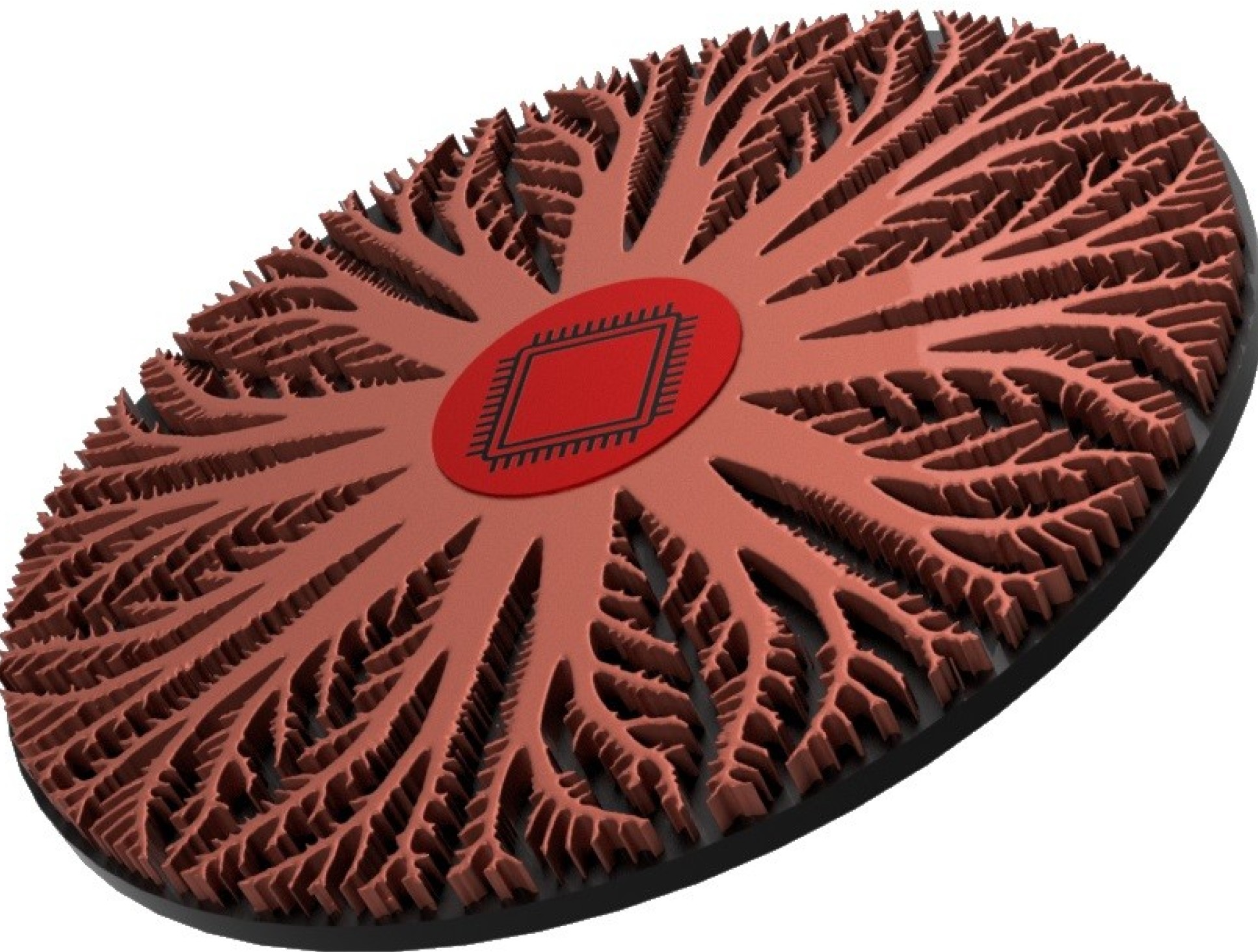

TOffeeAM was founded in 2019 by Professor Montomoli, Dr Marco Pietropaoli and Dr Audrey Gaymann from the Department of Aeronautics. Together they developed an AI system that replicates the work of highly trained and highly creative human engineers, but it does it faster and cheaper.

Combined with the latest advanced manufacturing technologies, such as 3D printing, TOffeeAM’s lightweight, low-waste designs can drive large carbon dioxide and pollution reductions, while increasing reliability and overall performance. The system can also make possible the wider use of sustainable fuels, the design of better batteries, the development of advanced nuclear technologies and other innovations needed for a sustainable future.

Innovate and accelerate

Completion of the venture funding round adds to a busy year for TOffeeAM. At the beginning of 2022, it was one of 10 companies selected to participate in Aerospace Xelerated, a 12-week accelerator programme run by Boeing for startups using AI and autonomous technology to address challenges across the aerospace and defence industries.

“We made new industrial contacts and we had the opportunity to present how the TOffeeAM platform can be used to redesign next generation of aircraft engines and aerospace systems for Net Zero,” said Dr Pietropaoli.

This is not the company’s only involvement with Boeing.

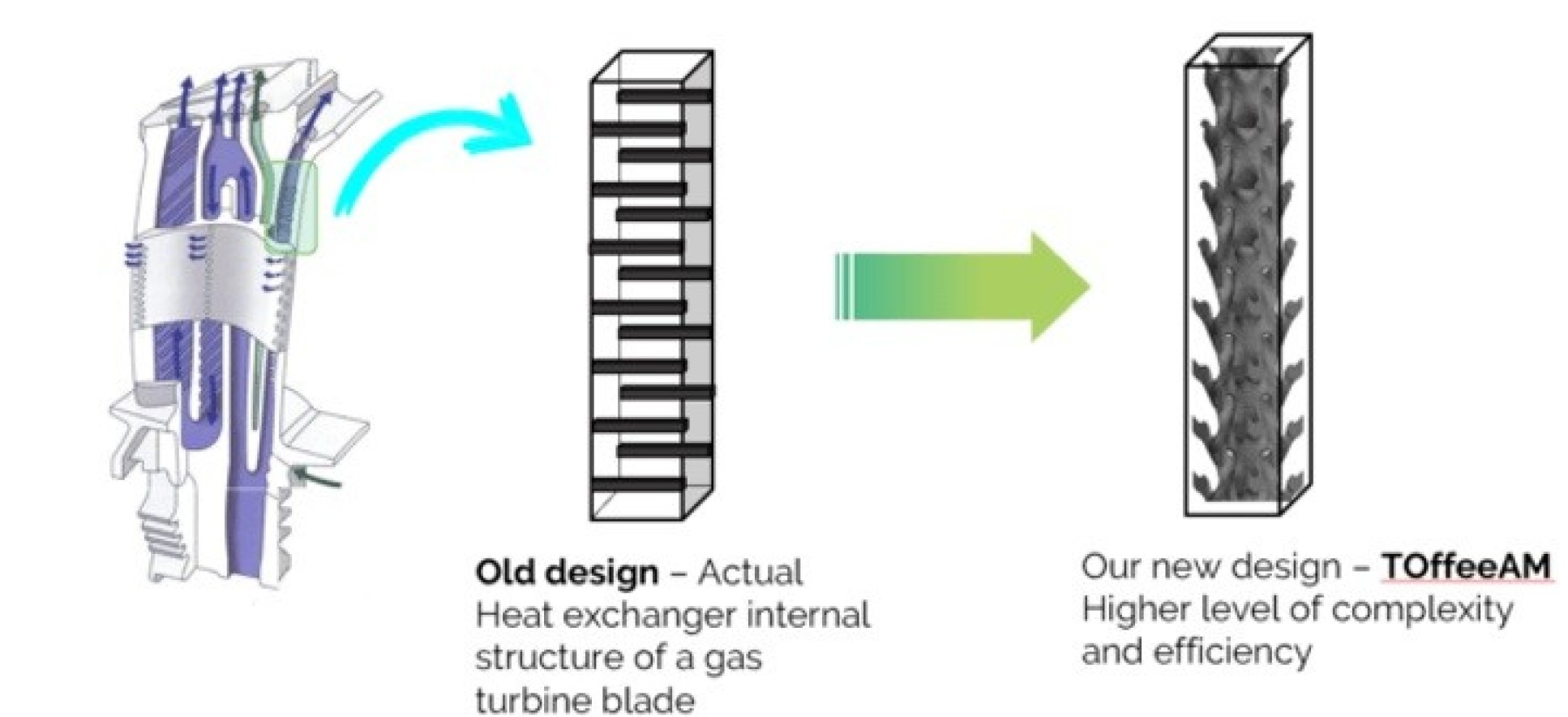

“In the past year, we have been lucky enough to work with Boeing in some very interesting areas, and it is exciting to collaborate with such international company.” Meanwhile, it has also been working with Rolls-Royce on a project optimising coolant systems in the electrification of aircraft engines, the results of which were presented at an American Society of Mechanical Engineers. “This has been a great opportunity for us,” Professor Montomoli says.

“This Innovate UK project gives us the possibility to work directly on a Net Zero challenge”, commented Dr. Audrey Gaymann, TOffeeAM.

Then in May, TOffeeAM was selected to receive up to £300,000 for an Innovate UK project to develop an AI-driven framework for next-generation heat exchangers. The aim is to produce an open-source, curated dataset for modelling turbulence in the design of printed circuit heat exchanger and cold plate cooling systems. These are used in many industries currently tackling electrification and striving to achieve Net Zero carbon emissions.

“This a very exciting project for TOffeeAM, giving us the possibility to work directly on a Net Zero challenge that requires better thermal conversion systems,” says Dr Gaymann. “This allows us to develop new features that will be used in our optimisation system, and to produce data that will be shared with the wider public.”

The latest injection of funding will allow TOffeeAM to pursue these developments, while scaling-up its business globally. While the focus will be on US and East Asian markets, the company’s headquarters will remain in the UK.

Find out more about toffeeam.co.uk.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.