Tractus3D is taking 3D printing high-performance materials to the next level with this month’s release of the T850P. A newly developed heated chamber provides thermal management in combination with a high temperature printhead.

Heat it up

With this innovative heated chamber, the temperature inside the T850P can easily be controlled. Thermal management helps to reduce warping because it diminishes premature cooling by open air. The heated chamber allows the user to set the temperature at the required level up to 65 degrees Celsius. The high temperature nozzle goes up to 450°C and the build plate up to 175 °C.

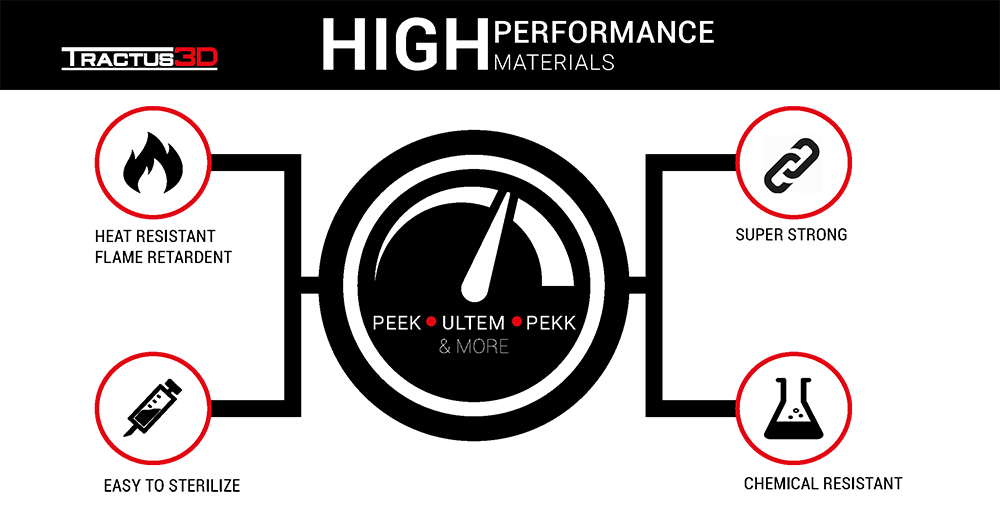

High-performance plastics

The T850P enables to create prototypes out of superior materials such as Carbon PEEK, PEEKQ and ULTEM. But conventional materials like PLA and PETG are also still printable. With a spacious build volume of 300mm x 380mm (diameter x height) this all-round 3D printer is extremely useful for small batch production.

According to Maurits Blok, Commercial Director of Tractus3D, the T850P is perfect to produce strong and lightweight objects, like items created with PEEK. Maurits Blok: “This material has properties that correspond to metals in terms of strength and heat and chemical resistance. Our clients find this material the ideal alternative for metal parts, and its applicable for medical applications as well, due to the sterilizability and biocompatibility of PEEK.”

Grow with technology

With the modular build of the 3D printers, new features simply can be added. Trelleborg Sealing Solutions, a prominent manufacturer of high tech sealing solutions, is one of Tractus3D’s long standing customers benefiting from this upgradability. They started off buying their first Tractus3D high temperature printer (V1) back in 2015, upgraded the printer to V2 in 2017 and are now upgrading to the latest technology of the T850P.

Innovation is essential

Trelleborg Sealing Solutions Malta boast 55 years of O-Ring and Engineered Molded Parts manufacturing experience, with an emphasis on technical performance and quality assurance.

‘‘During the years we have tested different types of high temperature 3D printers from manufacturers all over the world and we are definitely taking our 3D printing activities to the next level with the T850P,’’ says Ivan Gerada, Procurement & IT Manager. ‘‘We believe that innovation is essential to keep our leading position. With the help of Tractus3D printers we can achieve our goals and keep innovating in several fields’’.

Always fully covered

A Service Level Agreement is included for free with the T850P. As part of the SLA, customers receive a spare print head. In case a print head gets dirty, they can just swap the print heads and send Tractus3D the soiled one. It will be professionally cleaned at no cost. On top of that, the SLA provides unlimited support and discounts on filaments and upgrades.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.