Naval Postgraduate School (NPS) partnered with Commander, Naval Surface Force, U.S. Pacific Fleet (COMNAVSURFPAC) in facilitating the installation of a 3D printer on Wasp-class amphibious assault ship USS Essex (LHD 2) during Rim of the Pacific (RIMPAC) 2022. Essex is the first ship to participate in the initial testing and evaluation of the 3D printer during underway conditions to determine the printer’s viability when out to sea.

As a proponent of enhancing overall readiness of any warfighting organization, Lt. Cmdr. Nicolas Batista, the Aircraft Intermediate Maintenance Department (AIMD) officer aboard Essex, said “Having this printer aboard will essentially accelerate, enhance and increase our warfighting readiness.”

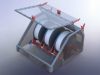

Batista stated this 3D printer, is one of the fastest printers on the market, capable of fabricating and printing aluminum up to 10” by 10”. Many common components may be created on the ship to include heat sinks, housings, fuel adapters, bleed air valves, valve covers and more.

“The capabilities of the 3D printer will enable Essex to become more self-sufficient,” said Batista.

He expressed that innovative operational concepts such as this 3D printing capability will be great additions in the future for every ship.

The next step in the evaluation of the printer will be to provide training to Sailors who will be using the equipment. As someone who enjoys hands-on learning, Aviation Structural Mechanic 3rd Class Roxanne Barrera expressed her excitement to be one of the first Sailors to receive this training.

“I was honored when my chain of command asked me to be the first Sailor aboard USS Essex to get the training for this 3D printer. I just want to learn how to operate it and share [the knowledge] with other people.”

While Essex has had the capability to manufacture small items needed on the ship, Aviation Electronics Technician 2nd Class Jonah Waage said, “We have never been able to make something with the precision and intricacy that this new 3D printer will provide which is important because it will contribute to saving time and money for our Navy in the long run.”

Batista stated that Commander Naval Air Force, U.S. Pacific Fleet (COMNAVAIRPAC) and Commander, Naval Air Systems Command (COMNAVAIRSYSCOM) have also initiated efforts to establish an AIMD work center, solely designed for the AM concept, and are striving towards the capability of fabricating needed aircraft parts with a 3D Printer.

“Additive Manufacturing (AM) has become a priority and it’s evident that AM will provide a greater posture in warfighting efforts across the fleet and will enhance expeditionary maintenance that contributes to our Surface Competitive Edge.”

During testing and evaluation at sea, a team aboard Essex will create various shipboard aluminum items with the 3D printer and provide feedback to NPS and COMNAVSURFPAC on the results.

Essex is ported in Pearl Harbor and participating in Rim of the Pacific (RIMPAC) 2022.

For more information, visit www.navy.mil.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.