Faced with rising monetary and environmental costs of obtaining, transporting and storing cadavers for teaching purposes, two University of Arkansas for Medical Sciences (UAMS) neurosurgeons believed there had to be a better, “greener” way.

Glenn Pait, M.D., director of the Jackson T. Stephens Spine & Neurosciences Institute and fellow neurosurgeon Noojan Kazemi, M.D., education director of UAMS’ Spine Neurosurgery Program, established a “green spine lab” at UAMS.

The unique experience materialized Dec. 12, on a day to allow neurosurgery residents to receive hands-on experience working on alternative cadavers in a didactic learning experience that included lectures by Pait and Kazemi.

Thanks to an educational grant from Globus Medical, Inc., three synthetic cadavers were provided to UAMS. Surgical Training and Utility Devices distributes the realistic models used in the institute’s surgical laboratory. Twelve residents, medical students and faculty members preformed procedures on the 3D-printed cadaver alternatives.

Kazemi said the synthetic cadavers have skin and bone that looks and feels realistic, and because they aren’t human specimens with issues of preservation or deterioration, they are perhaps more useful than actual cadavers.

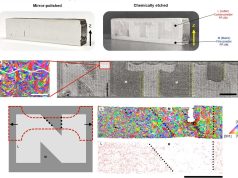

The models have “a corticocancellous architecture that mimics human bone,” that provides “excellent radiographic anatomy” and “permits the use of injectable bone cements.”

A few other teaching hospitals across the country have phased out the use of cadavers in favor of virtual reality or augmented reality options – letting students view a virtual body’s internal workings three dimensionally or having them don goggles that superimpose digital imagery onto a tangible surface. However, UAMS is unique in using synthetic, 3D-printed cadavers to train future neurosurgeons, Pait said.

“The hands-on experience provided by these synthetic specimens is an invaluable learning tool. Particularly, for the junior residents, this experience develops greater understanding and confidence in the operating theater,” Pait said.

Called SurgiSTUDs (Surgical Training Utility Devices), the company that makes them says they can be customized to accommodate the part of the body and the conditions emphasized in each lab. They come as whole bodies or just sections, such as torsos.

“It is a safer and more affordable approach to medical education that provides the same educational experience as traditional cadavers,” John Brambert, executive vice president of SurgiSTUD, said in introducing the synthetic models in late 2021.

In the last year or so, Kazemi said, The cost for using actual cadavers has risen dramatically. He cited difficulties obtaining them through cadaver banks, expenses of transporting them with proper equipment to a lab that has appropriate facilities for handling and storing them, and later ensuring that they are returned for burial or other final disposition.

Kazemi said Pait proposed turning the UAMS spine lab into a “green lab” to avoid the escalating monetary costs and eliminate disposal costs, but also to contribute to a larger goal at UAMS to increase sustainability and minimize the lab’s carbon footprint.

“So we searched for companies and resources that would have an alternative to cadavers, and we found a company whose 3D-print models are made of various material that highly resembles the anatomy of the relevant part of the cadaver that we are interested in – the spine.”

This hands-on experience used three lumbar spines, which included the thecal sac filled with water to resemble a life-like experience. The residents opened the dura and practice suturing and repairing the dura.

The residents also had access to imaging, Kazemi said.

“So they not only did dissections, but also practiced placing spinal instrumentation, which included bone/pedicle screws and rods – again, courtesy of Globus, Inc.”

“We took a survey of the residents’ knowledge and abilities beforehand and afterwards, and uniformly, the response indicated that they experienced a significant learning benefit,” Kazemi said.

He said that once the lab is finished with the synthetic cadavers for the semester, they can be disposed of, or the chassis can be reused in another lab after being supplied with new parts.

“There are many advantages” to using the 3D specimens, Kazemi said. “First, the transportation costs are significantly reduced because there is no handling of a biological specimen. Secondly, when they come to UAMS, they can be stored in a dry space. We don’t need to store them refrigerated or frozen, and there is no time limit on how long they can be kept here.”

Disposal costs are nonexistent, he said.

“We’re talking about roughly a $2,000 to $3,000 cost difference,” between a human cadaver and a synthetic cadaver, he said.

“The use of synthetic spine models in the laboratory is a first step for building surgical confidence of residents, Pait said, adding that “human cadavers should be used for more advanced study and experience.”

Find out more about the UAMS at uams.edu.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.