Velo3D and Incodema3D today announced their partnership to drive technology adoption of metal additive manufacturing. The partnership brings together Velo3D’s Sapphire™ 3D print system and Flow™ software with Incodema3D’s production scale manufacturing capability, enabling greater innovation for design and production of parts.

“Velo3D’s Sapphire system is a unique solution with its first of a kind in-situ metrology and real time close-loop control. It enables customers to truly control the quality of additive manufacturing on every part,” says Scott Volk, CTO at Incodema3D. “Through this partnership with Velo3D we can provide our customers with new levels of production services and unlock new designs at unprecedented levels of quality control.”

“The technology adoption partnership with Incodema3D is very strategic for us,” said Benny Buller, CEO of Velo3D. “Incodema3D has a very strong track record in the metal additive manufacturing industry delivering 3D printing services to leaders in the aerospace, energy and industrial applications. We anticipate our collaboration will start a new wave of growth for the industry.”

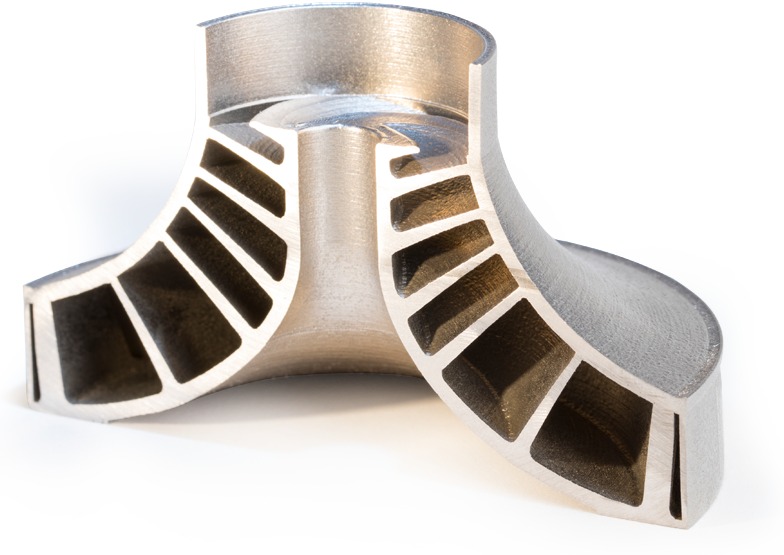

Velo3D offers end-to-end metal additive manufacturing (AM) solutions comprised of the Sapphire production system, Flow print preparation software, and Intelligent Fusion™ technology. Together, the solutions solve some of the most difficult AM challenges including product design limitations, part-to-part consistency, process control and cost-effective manufacturing. The Sapphire system is a laser powder bed metal additive 3D printing system designed for high volume manufacturing. Sapphire is capable of building complex geometries including designs with overhangs that are less than five degrees and large inner diameters without supports – something previously unheard of in the AM industry.

“Velo3D’s technology provides unique capabilities that enable designs we previously could not fulfill,” said Greg Galvin, executive chairman, Incodema3D. “The Velo3D Sapphire solution

complements our manufacturing capacity and opens the door to new production opportunities that will drive further adoption of metal additive manufacturing. We look forward to accelerating our growth with this partnership.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.