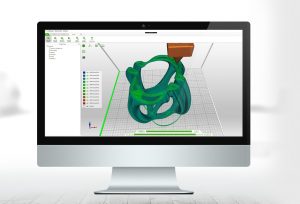

Less than a week ago, VERASHAPE announced they’re conducting programming work on software based on Parasolid Communicator to support preparation of models for printing. Now, the company informs that Beta Testing of the newest version of their application is about to begin. Candidates interested in SOFTSHAPER 2018 testing can already contact the producer of the software.

Verashape with the license from SIEMENS PLM Software is among the first producers of 3D Printers to create software based on Parasolid Communicator to support the import and proper preparation of models for printing.

When conducting programming work we strive to make the software we create a universal solution aiding the print preparation process regardless of the type of 3D Printer used for printing. Therefore, we invite the users of all types of 3D Printers to become Beta-Testers of the newest version of the application – says Tomasz Szymański, the founder and CEO of VERASHAPE.

Candidates interested in SOFTSHAPER 2018 testing can contact the producer of the software to apply via a dedicated website www.softshaper.com, where basic information on the software can also be found.

The brand of the device used by our Beta-Testers is completely irrelevant. Our aim is to make our solution compatible with any 3D Printer – adds Seweryn Nitek, Software Engineer from VERASHAPE, one of the creators of SOFTSHAPER Software.

The creators of the software are looking forward to be contacted by 3D Printers producers interested in using SOFTSHAPER with devices produced by them, as well as filament producers who wish to share the parameters of their devices in the material database of the available application.

The creators of the software are looking forward to be contacted by 3D Printers producers interested in using SOFTSHAPER with devices produced by them, as well as filament producers who wish to share the parameters of their devices in the material database of the available application.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.