Wematter, a Swedish manufacturer of SLS 3D printers will launch a new version of the Gravity SLS 3D printing system at Formnext 2022. It is a complete system for speeding up R&D processes at companies with several R&D and technology development centers. It will support integration between geographically dispersed teams, facilitate a quicker and fuller understanding of ideas and concepts across countries and continents, and will typically cut development times by three quarters.

The Wematter SLS 3D printing system includes five parts, integrated into clever ways to enable easy handling. It is as easy to handle and install as a copier machine or a domestic fridge. The whole system can be brought through a domestic door and be kept in a relatively small room.

1. Gravity SLS 3D printer: As of Formnext 2022, the upgraded and improved Gravity 2023 can print well over 20 different materials. It’s quipped with a high-power (50 W) CO2 laser combined with a high-speed laser scanning assembly. Through new components and algorithms, the scanning speed has been increased by 200 %, increasing the print speed accordingly.

2. Density water-jet cleaning cabinet: used for the depowdering of 3D-printed parts. Out of all the units provided by SLS printer producers, this is one of the fastest and cleanest of them all, since it uses high-pressure water. It is a closed system, without needing plumbing or water connection. Density 2023 is also more durable than previous versions and can handle a more extensive variety of print models.

3. Deep Space software: tailored specifically for Gravity it automates the workflow to a large extent. Preparing the build becomes a quick and rewarding exercise, finished in no time. Anyone in the organization will learn Deep Space in an hour. Engineers and product developers will have even more fun developing new components. The focus of the 2023 upgrade is on user experience and many new algorithms and solutions under the hood to create a fluent and swift process from import to print.

4. Atmosphere: ensures a stable atmosphere in the build chamber of Gravity. This unit is key to print quality. It is delivered as a separate unit to simplify transportation and placement of the system and service.

5. Inertia: effective and easy-to-use powder collector used to vacuum most powder from the Gravity build volume after finished print, before the printed parts are moved to Density for cleaning. This ensures minimum powder spillage and a more ergonomic workflow.

New polymer material for SLS 3D printing

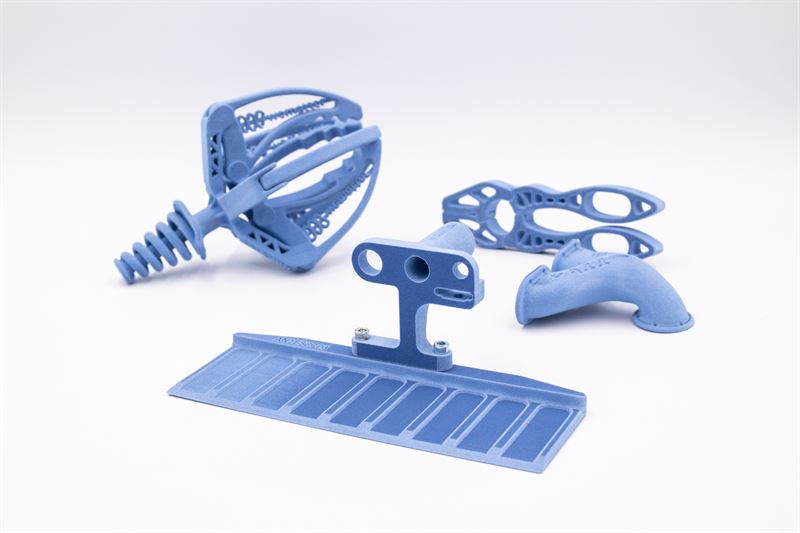

Just as important as the system itself are the materials it can print. As part of Wematter’s strategy, the material portfolio is once again expanding. A special focus is on food-grade components and for that application, the biggest news is Aurora PA11 Food Grade – a blue polymer which is approved for contact with food. The blue color makes it easy to spot broken parts that could fall into the food during production.

“With the Gravity 2023 system, we now have the most competitive offer for any R&D department that has people working in different locations”, says Robert Kniola, founder and CEO at Wematter.

If you are planning to visit the Formnext 2022 exhibition, you can drop by the Wematter booth B69 in hall 11.1 and see all the polymer materials and the Gravity 2023 SLS 3D printing system.

For more information, please visit wematter3d.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.