Worcester Polytechnic Institute has deployed 3DPrinterOS to manage its 3D printing operations. The cloud-based platform streamlines and centralizes operations.

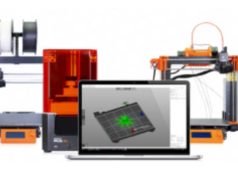

Worcester Polytechnic Institute (WPI) has been employing 3DPrinterOS since the makerspace’s inception in 2018, streamlining their 3D printing operations. The makerspace manages all its 3D printers through the 3DPrinterOS queue, allowing students to queue their parts to a virtual printer. For students paying out of pocket, they come and pay for it before the parts are released to an actual print queue on a first-come, first-serve basis. For classes and faculty-based projects, payments are automatically deducted from their balances.

This is a high-volume queue, with the makerspace typically processing between 300 to 400 kilograms of filament annually. 3DPrinterOS has been instrumental in managing the queue efficiently, allowing the makerspace to utilize the printers to their fullest potential. The makerspace started with 24 3D printers and, in the past year, has added three more.

The makerspace at WPI has a significant number of users, with approximately 1500 to 1800 unique users utilizing it each year. While the main users are mechanical engineering and robotics engineering students, there is participation from other departments, including game development, humanities, art, architectural engineering, civil engineering, chemical physics, and more. The makerspace provides workshops tailored to specific groups to encourage involvement from across the campus.

“The makerspace at WPI is designed to remove barriers to innovation,” says Mitra Anand, the advanced technology and prototyping specialist who leads the makerspace prototyping at Worcester Polytechnic. “We are committed to providing students access to cutting-edge equipment and technology, regardless of their financial situation. This commitment is reflected in the makerspace being open to all students, regardless of their major or year of study.”

When Mitra first joined Worcester Polytechnic, the makerspace building was an empty shell with a few scattered pieces of equipment. He has been involved in the journey from those beginnings, building a program, developing the community behind it, and overseeing the day-to-day operations.

“It’s definitely a good problem to have,” Mitra adds. “We have an amazing group of students working on solving real-world problems using these printers, as opposed to if all these machines were sitting there collecting dust. There is actually not enough capacity, and we need more of them.”

In addition to the wide range of equipment and tools, the prototyping lab houses FDM printers, carbon dioxide-based laser cutters, a PCB structuring machine, and a desktop water jet.

By employing 3DPrinterOS, WPI has connected mentors, students, and the community with a 3D printer program and removed barriers and fear of failure. The program has been so successful that the makerspace has plans to expand its printing capabilities in the future.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.