3dk.berlin enhances the possibilities of standard 3D printers (FDM): With k-top – the new developed filament – prints are now temperature resistant up to 230 °C.

The material is suitable not only for building models and making things but also for industrial appliances such as small series, prototypes and tightly measured objects.The thermoplastic compound offers all new possibilities. Volker Bernhardt, CEO of 3dk.berlin: “Temperature resistant objects near motor compartments or hotends can be printed reliably now.” As a big bonus, the new material is mechanically stronger than PLA or ABS.

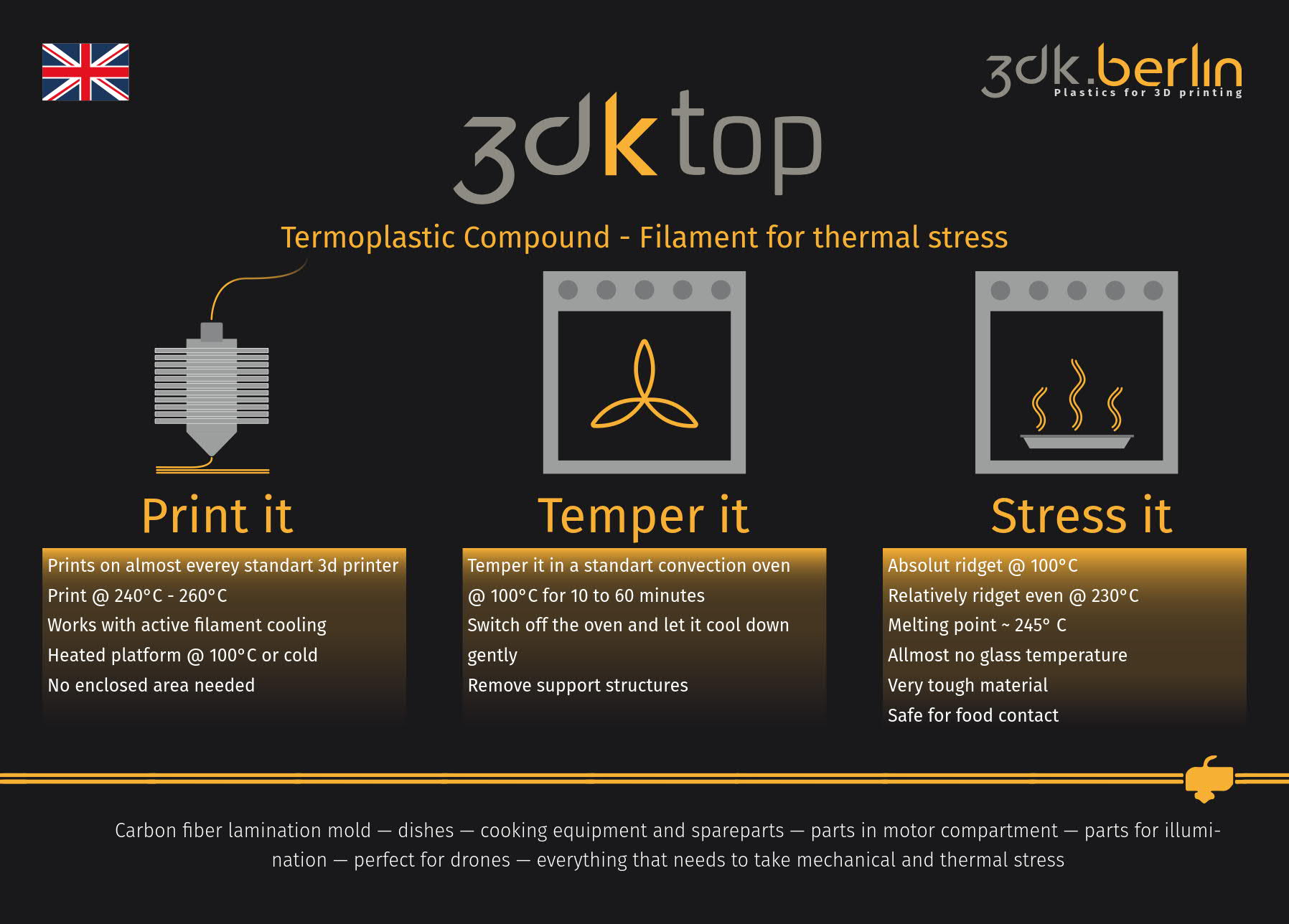

3dk.berlin developed the new material for industrial customers and started a piloting campaign in partnership with a big automotive customizer. The campaign showed to be fully successful and now 3dk.berlin offers their new material k-top to home consumers. The material is suitable for all standard 3D-FDM-printers which can hold temperatures of 260 °C. A heated bed or a heated printing chamber aren´t necessary. k-top prints docile, accepts active cooling and owns a great inter-layer adhesion. After printing the parts they get tempered at least 110°C inside a convection-oven and cooled down slowly.

The proper tempering time depends strongly on the volume of the built object – it has to be heated thoroughly.

The 4th dimension shows itself while crystallizing the material, which triggers the structural change of the material. Thus a thermal resistance of 200 °C (constant load) or 230 °C (peak) is reached.

If crystallization is spared, the print result is extremely impact resistant and can take huge mechanical loads. Temperature resistance is located at 80°C in this case. 3dk.berlin is a division of Bernhardt Kunststoffverarbeitungs GmbH, which has produced foils, plastic parts, and specialized materials for over 50 years now. The company produces in Germany and is highly experienced in installation engineering and developing and processing synthetic materials. Partnerships exist with Fraunhofer Institute and the University of Rostock. The filament processers from Berlin expand the filament unit since 2013 in their HQ in Berlin Heiligensee.

The premium filaments “made in germany” are easy to process, due to their special compounding of raw materials and their high consistency. 3dk.berlin offers biological degradable PLA-filament in every custom and 100 standard colors, flexible bio filament (WillowFlex), specialized materials and their new material k-top. The technical synthetic is made from food safe raw materials – just like every filament in 3dk´s range. k-top is offered in black, gray and white and is available in 1.75 and 2.85 millimeters in diameter. One spool of 300g costs 29,90€ including tax and can be ordered directly at 3dk.berlin or at qualified specialty stores.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.