ALIO Industries, a leading supplier of precision nanometer-scale motion controls, meets the demanding requirements of OEMs producing cutting-edge 3D metrology tools in a dynamic and increasingly competitive sector where the industry demands ever more accurate measurement solutions.

High-quality sensors and encoders are essential for accurate measurements. But the performance of these components is closely linked to the underlying motion system.

“There are several reasons for this. The motion system is responsible for the precise positioning and movement of the sensors and encoders during the measurement process,” explains Bill Hennessey, Founder and President of ALIO Industries. “Any errors in the motion system, such as mechanical backlash, hysteresis, or non-linearity, can introduce inaccuracies in the measurements, regardless of the quality of the sensors and encoders. By ensuring that the motion system is of equal or superior quality, these errors can be minimized, allowing the high-performance sensors and encoders to operate at their full potential.”

Stability and precision of the motion system are critical to maintaining the position and orientation of the sensors and encoders during measurements. In addition, the resolution of the motion system directly affects the measured values.

In many 3D measurement applications, precise synchronization of the movements of different sensors and encoders is required. A high-quality motion system ensures that the various components can be accurately adjusted.

Speed and responsiveness of the motion system are also critical factors. The motion system should move the sensors and gauges quickly and smoothly without causing errors or delays in measurements.

By using a superior motion system, manufacturers can ensure that their measurement devices are future-proof.

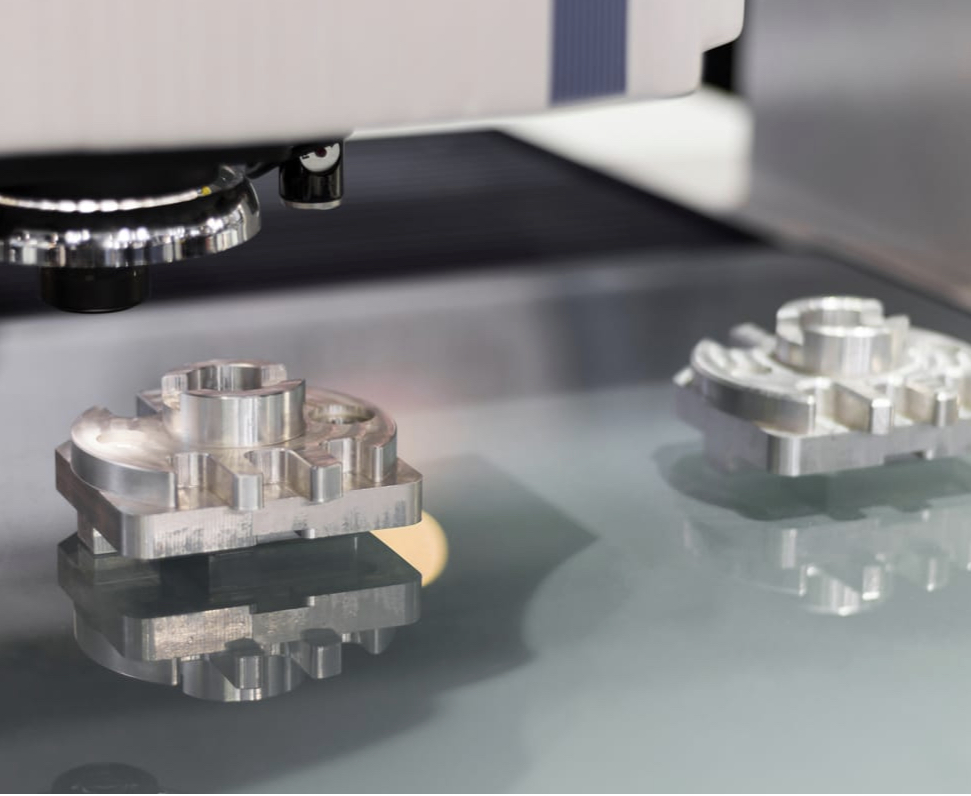

“For such applications, ALIO provides near air-bearing performance crossed roller bearing XY Nano Metrology stages with up to 450mm travel range,” explains Hennessey. “These stages use DC Servo linear motors with unmatched motion performance with 3-Sigma, 6-D (linear, straightness, flatness, pitch, yaw and roll) and bi-directional repeatability of less than +/- 250nm. In other words, the volumetric bi-directional repeatability of any XY point is within a sphere of 500nm or less.”

These stages are ideal for motion control solutions ranging from compact 2D systems to wide field-of-view (FOV) 3D metrology tools, and are ideal for various industrial and scientific applications where high-performance motion control is required.

Find out more about ALIO Industries at alioindustries.com.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.