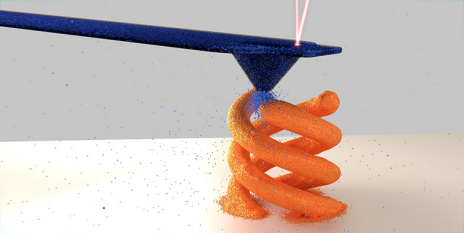

Researchers at ETH Zürich developed a technology for 3D printing microscopic metal structures.

The technology was invented years ago by researchers at ETH Zürich for their biological research. Now it was enhanced for the use with materials like copper. The ETH spin-off Cytosurge AG will now develop this technology  even further.

even further.

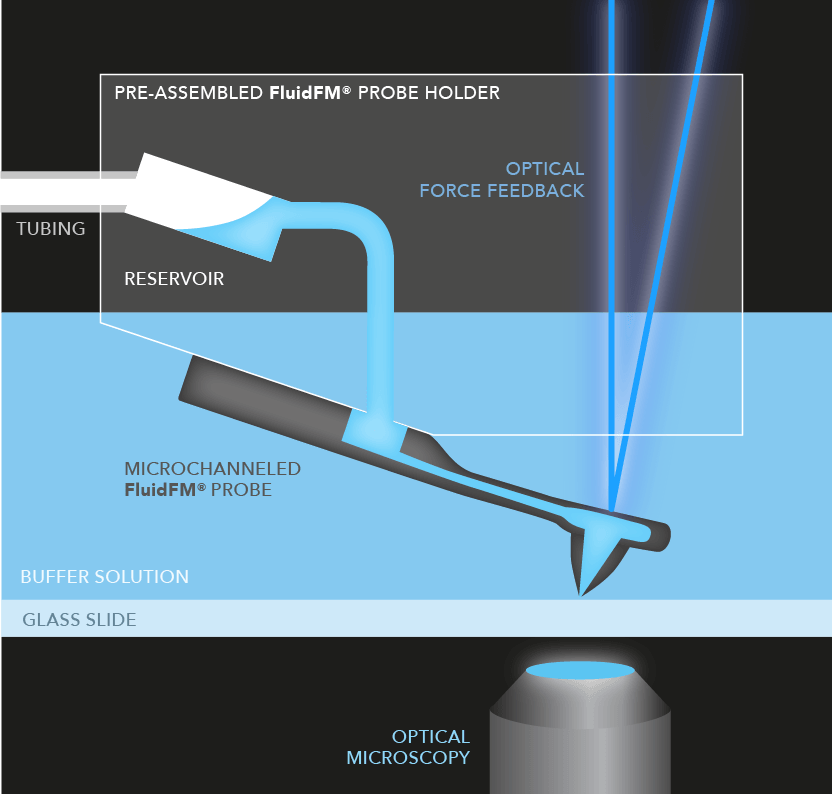

The FluidFM technology utilises a very small pipette that has an aperture 500 times smaller than the diameter of a human hair. Through this 300 nanometers (nm) small opening flow rates as small as femtoliters (fL) per second can be archived. At the moment Cytosurge used a copper sulfate solution which chemically reacts with an electrode to produce solid copper objects on a build platform of gold.

Tomaso Zambelli, associate lecturer and group leader at the Laboratory of Biosensors and Bioelectronics at ETH Zurich:

“This method can be used to print not only copper but also other metals. FluidFM® may even be suitable for 3D printing with polymers and composite materials.”

One of the significant advantages of FluidFM is that it is possible to measure the forces at the tip of the pipette. Luca Hirt, a doctoral student at ETH Zürich, is the inventor of this new developed technology:

“We can use this signal as feedback. Unlike other 3D printing systems, ours can detect which areas of the object have already been printed. This will make it easier to further automate and scale the printing process.”

Cytosurge will evolve their existing product line in order to make this new 3D printing technology available to interested researchers in the industry as well as at universities. The company also plans an independent product line for industrial applications.

Dr. Pascal Behr, co-founder and CEO of Cytosurge states:

“The newly developed 3D printing method is suitable for applications in various markets. Presently we see potential applications especially in the watch- and semiconductor industry as well as in medical device sector. It offers our customers interesting growth potential and possibilities to increase efficiency.”

Yesterday the journal Advanced Materials published a paper about the 3D Microprinting of metals from Luca Hirt, Stephan Ihle, Zhijan Pan, Livie Dorwling-Carter, Alain Reiser, Jeffrey M. Wheeler, Ralph Spolenak, János Vörös und Tomaso Zambelli.

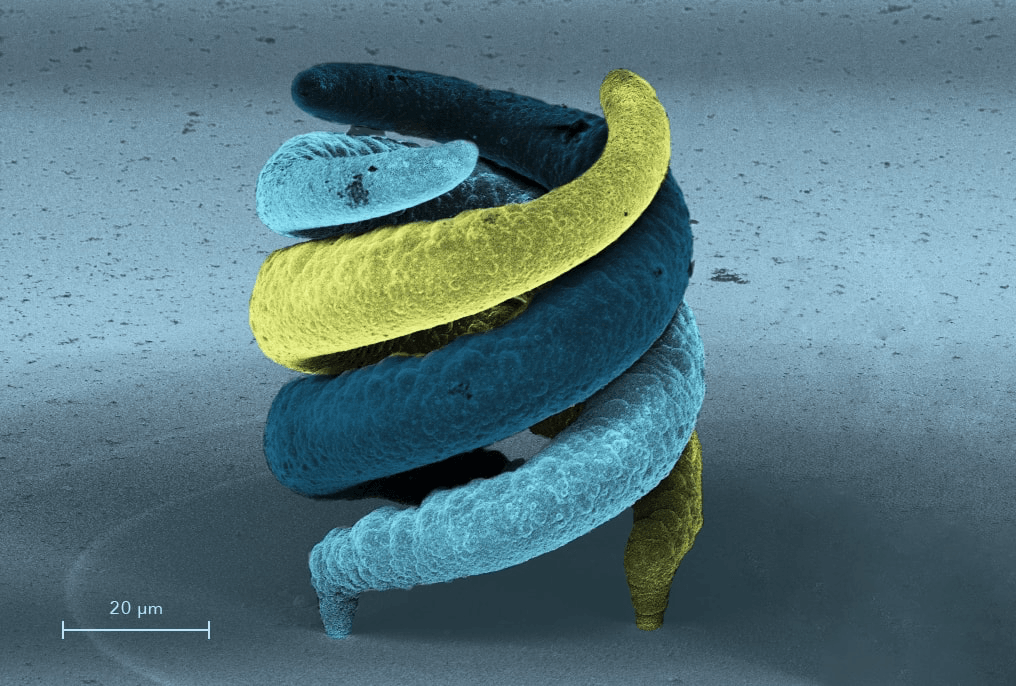

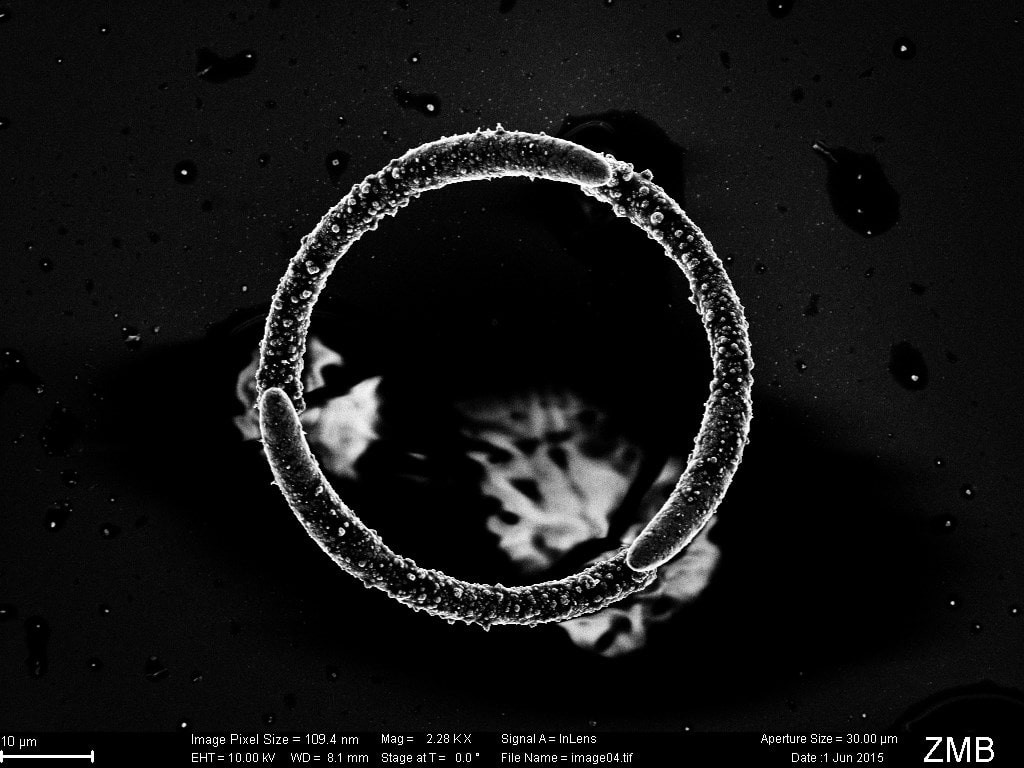

A structure produced with FluidFM:

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.