Researchers at the University of Massachusetts Amherst have used laser-based 3D printing to form high-entropy alloys (HEAs) that are stronger and much more ductile. They used neutron and X-ray scattering and electron microscopy to better understand the mechanisms of these performance improvements.

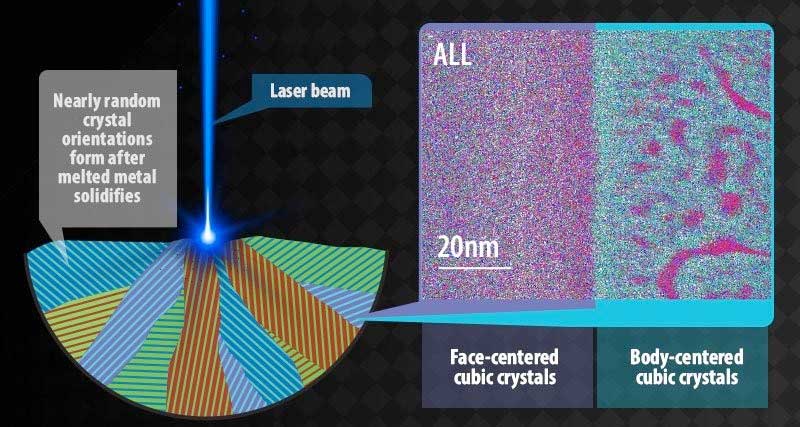

They used neutron and X-ray scattering and electron microscopy to better understand the mechanisms of these performance improvements. The laser-based AM technique led to the formation of nanometer-thick nano-lamellas that provide high strength while their edges allow for some ductility. The alloys consisted of alternating layers of face-centered cubic and body-centered cubic crystal structures. The newly developed HEAs showed exceptionally high yield strengths of about 1.3 gigapascals and elongation of about 14%, which is higher than other AM metal alloys.

This development could revolutionize the production of durable, reliable and fracture-resistant HEA parts for industry. Such alloys could be used, for example, in the production of safer and more fuel-efficient vehicles, stronger products and durable machinery. In addition, laser-based AM, in which lasers fuse powder alloys into solid metal forms, is highly energy efficient and therefore attractive for the production of new types of HEA.

The investigation of the mechanical load distribution inside the HEA samples under load was carried out at the Spallation Neutron Source of the Department of Energy (DOE) at Oak Ridge National Laboratory (ORNL). Detailed 3D images of the composition and microstructures were taken with an atom probe tomograph at the Center for Nanophase Materials Sciences, also a DOE user facility at ORNL. Phase studies of various samples were performed using X-ray diffraction at the Advanced Photon Source, another DOE user facility at Argonne National Laboratory. The research was supported by the National Science Foundation, the University of Massachusetts Amherst and the Laboratory Directed Research and Development program at Lawrence Livermore National Laboratory.

The new findings in the production of high-entropy alloys using 3D printing open up new possibilities for materials science and additive manufacturing. This technological innovation promises not only to improve existing products and processes, but also to open up new areas of application for high-strength yet malleable materials.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.