Researchers have shown for the first time that 3D-printed polymer-based micro-optics can withstand the heat and power levels in a laser. This advance enables low-cost, compact and stable laser sources that could be useful for a variety of applications, including lidar systems for autonomous vehicles.

“We significantly reduced the size of a laser by using 3D printing to fabricate high-quality micro-optics directly on glass fibers used inside of lasers,” said research team leader Simon Angstenberger from the 4th Physics Institute at University of Stuttgart in Germany. “This is the first implementation of such 3D-printed optics in a real-world laser, highlighting their high damage threshold and stability.”

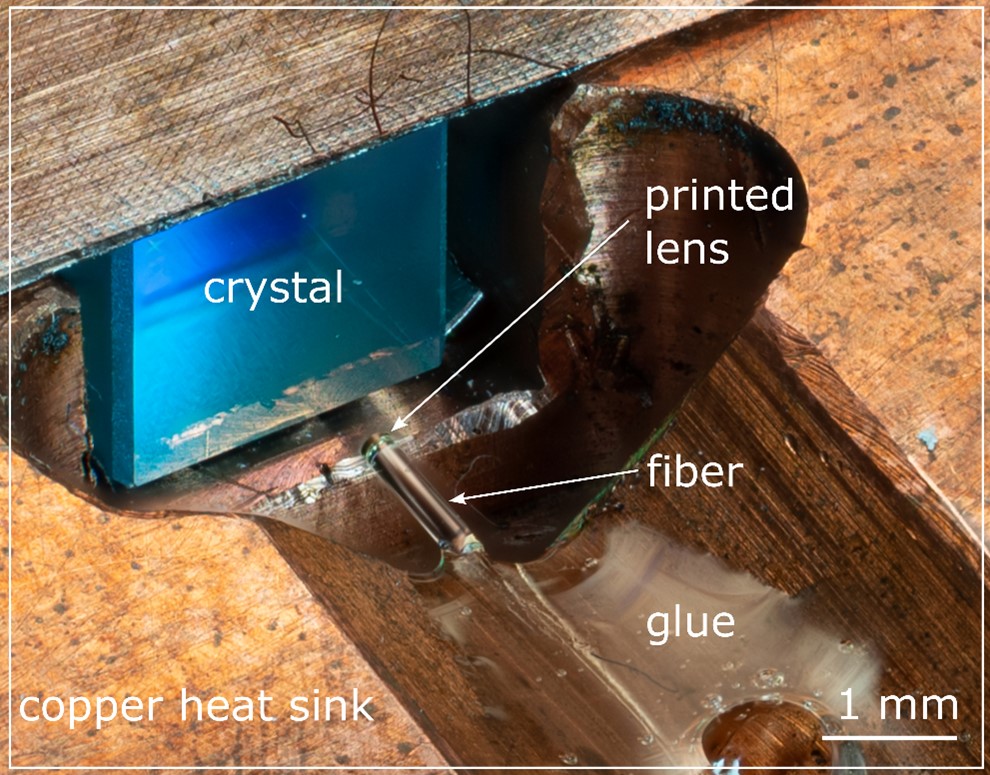

In the journal “Optics Letters” published by the Optica Publishing Group, the researchers describe how they 3D printed micro-optics directly onto optical fibers. This made it possible to combine fibers and laser crystals in a single laser resonator in a compact way. The resulting hybrid laser showed stable operation at output powers of over 20 mW at 1063.4 nm and reached a maximum output power of 37 mW.

The new laser combines the compactness, robustness and cost-effectiveness of fiber-based lasers with the advantages of crystal-based solid-state lasers, which can exhibit a wide range of properties such as different powers and colors.

Until now, 3D-printed optics have mainly been used for low-power applications such as endoscopy.

“Until now, 3D-printed optics have primarily been used for low power applications such as endoscopy,” said Angstenberger. “The ability to use them with high power applications could be useful for lithography and laser marking, for example. We showed that these 3D micro-optics printed onto fibers can be used to focus large amounts of light down to a single point, which could be useful for medical applications such as precisely destroying cancerous tissue.”

“Interestingly, we found that the printed optics were more stable than the commercial fiber Bragg grating we used, which ended up limiting our maximum power,” said Angstenberger.

The stability and efficiency of 3D-printed micro-optics in high-power lasers represents a significant advance in laser research and application. The University of Stuttgart is now working on optimizing the efficiency of the printed optics to further improve the output power. This development opens up new possibilities in various application areas and underlines the potential of 3D printing in the high-precision production of optical components.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.