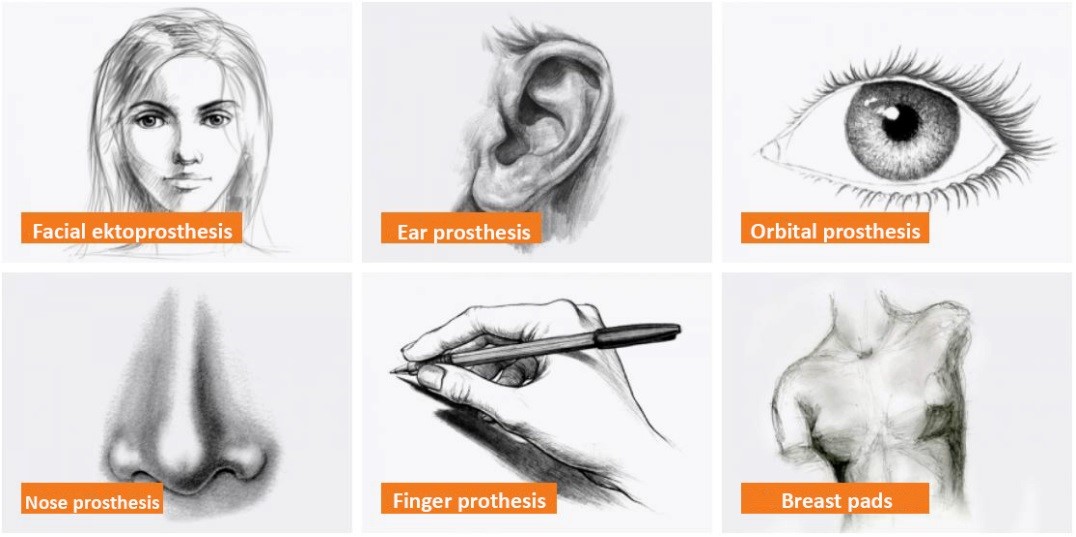

In December 2017, ISTOK AUDIO, a large Russian medical manufacturer, largely known for its superior, custom-made hearing aids, purchased their first Drake Mini scanner. The company wanted to harness the power of 3D scanning to create more realistic face-prosthetics (i.e. ears, eyes, chins, noses) in their Protez-Studio subsidiary.

Istok Audio’s manufacturing facility

Istok Audio’s manufacturing facility

Facts:

- Scanner: Drake Mini

- Used for: Scanning parts of the human face (ears, noses, eyes, etc)

- Average Scanning Time: 5 minutes

- Post-processing: 15-20 minutes

- Frequency of use: 3-5 times per week

- Software used: Thor3D Suite, Blender, Meshmixer

- Computer used: Win 10, i7 3.6 GHz processor, Nvidia GeForce GTX 1050Ti video card, 16GB of RAM

- 3D printer used: 3DSLA

- Filament used: Photopolymer – «Oy vsyo, RED» (roughly translated as “Oh, that’s it – RED”)

- Time to learn to use the scanner/software: 4-5 tries to feel comfortable

The process:

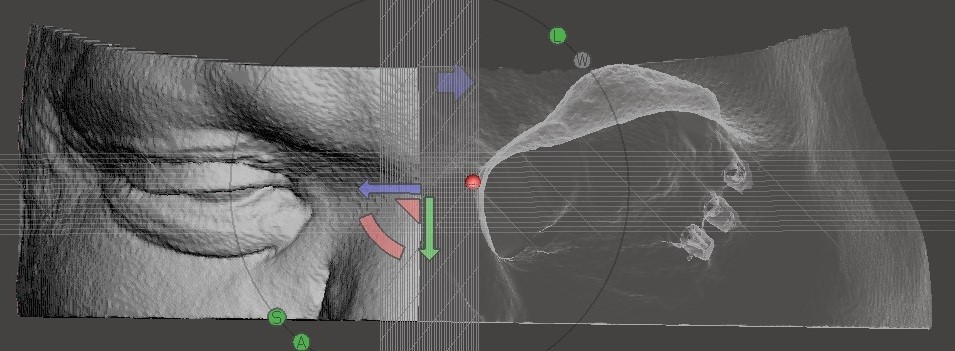

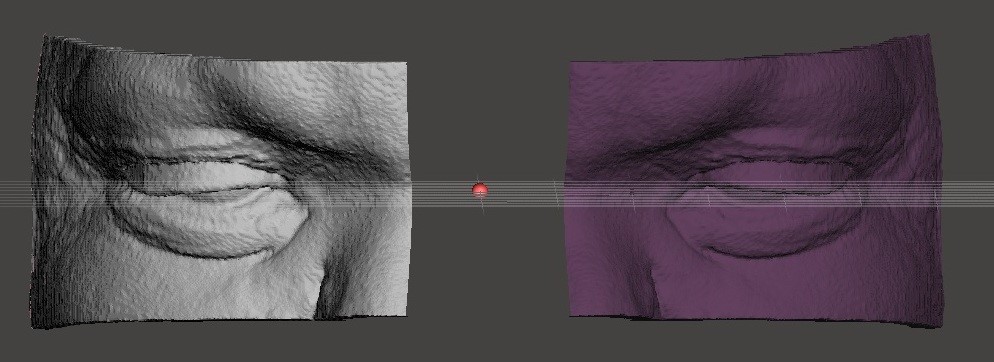

A technician scans the patient’s affected part of the face. Post-processes the scan in Thor3D Suite and exports to Blender and Meshmixer software to develop a custom prosthetic.

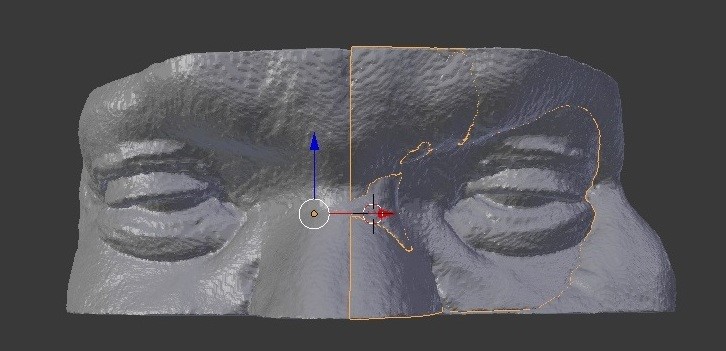

The image is cropped, mirrored and the final product is drawn in 3D.

The model is made into a mold on a stereolithographic 3D printer from 3DSLA. Once the prosthetic is ready, it is fitted on the patient to make sure it is comfortable.

Useful comments from Sergey Gladchenko, Head of the Production department:

- “Our company also owns a Rapidshape and Envisiontecprinters, and those can also be used for the printing of the mold, but their higher quality and price of materials is not necessary for this application.”

- “Initially, post processing of the models took around 30 minutes. We invested in a new, powerful laptop and the processing time was reduced in half.”

- “The most useful aspect of using the Drake Mini scanner was the significant reduction in time when scanning our youngest clients. Working with children was always rewarding, but now is also simple because scanning is quick and even if the patient moves during the process, the software can correct for that.”

Find more about other areas of use of Thor3D scanners.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.