MIT researchers have used 3D printing to create self-heating microfluidic devices, demonstrating a technique that could one day be used to rapidly produce inexpensive yet precise instruments to detect a variety of diseases.

Microfluidics refers to miniaturized machines that manipulate fluids and enable chemical reactions. This technology is already being used in home testing kits for COVID-19. However, many microfluidic applications require chemical reactions to be carried out at specific temperatures. Traditionally, such devices are manufactured in clean rooms and equipped with heating elements made of gold or platinum, which is a complicated and costly process.

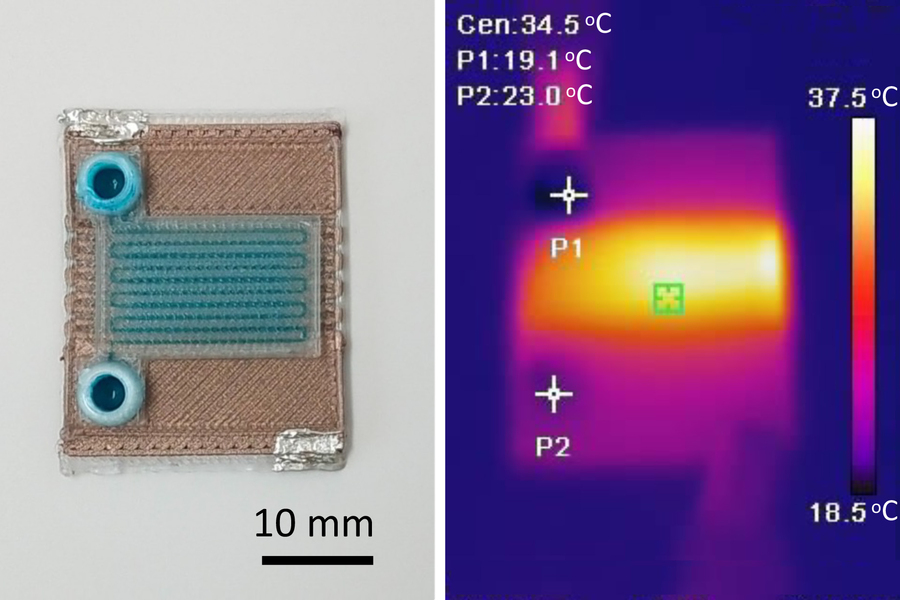

The MIT team has now developed a cost-effective method that uses multi-material 3D printing to produce self-heating microfluidic devices with integrated heating elements in a single fabrication step. These devices can heat liquid to a specific temperature as it flows through microscopic channels in the device.

The technique is customizable, allowing microfluidic devices to be created that heat fluids to a specific temperature or heating profile within a specific area of the device. The low-cost manufacturing process requires about $2 worth of materials for a ready-to-use microfluidic device.

This method could be particularly useful for creating self-heating microfluidic devices for remote regions in developing countries, where expensive laboratory equipment for many diagnostic procedures is often unavailable.

“Clean rooms in particular, where you would usually make these devices, are incredibly expensive to build and to run. But we can make very capable self-heating microfluidic devices using additive manufacturing, and they can be made a lot faster and cheaper than with these traditional methods. This is really a way to democratize this technology,” says Luis Fernando Velásquez-García, a principal scientist in MIT’s Microsystems Technology Laboratories (MTL) and senior author of a paper describing the fabrication technique.

The new manufacturing method uses a technique called multi-material extrusion 3D printing, in which multiple materials are layered through the printer’s many nozzles to create the device in one step. To create self-heating microfluidics, the researchers used two materials: a biodegradable polymer called polylactic acid (PLA), which is commonly used in 3D printers, and a modified version of PLA that contains copper nanoparticles and converts the insulating material into an electrical conductor.

“In Japanese culture, it’s often said that beauty lies in simplicity. This sentiment is echoed by the work of Cañada and Velasquez-Garcia. Their proposed monolithically 3D-printed microfluidic systems embody simplicity and beauty, offering a wide array of potential derivations and applications that we foresee in the future,” says Norihisa Miki, a professor of mechanical engineering at Keio University in Tokyo, who was not involved with this work.

“Being able to directly print microfluidic chips with fluidic channels and electrical features at the same time opens up very exiting applications when processing biological samples, such as to amplify biomarkers or to actuate and mix liquids. Also, due to the fact that PLA degrades over time, one can even think of implantable applications where the chips dissolve and resorb over time,” adds Niclas Roxhed, an associate professor at Sweden’s KTH Royal Institute of Technology, who was not involved with this study.

The research results will be presented at the PowerMEMS conference and could enable far-reaching applications in biomedical research and diagnostics.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.