Researchers at the Purdue University in Indiana have developed new software algorithms to significantly reduce 3D printing time and material.

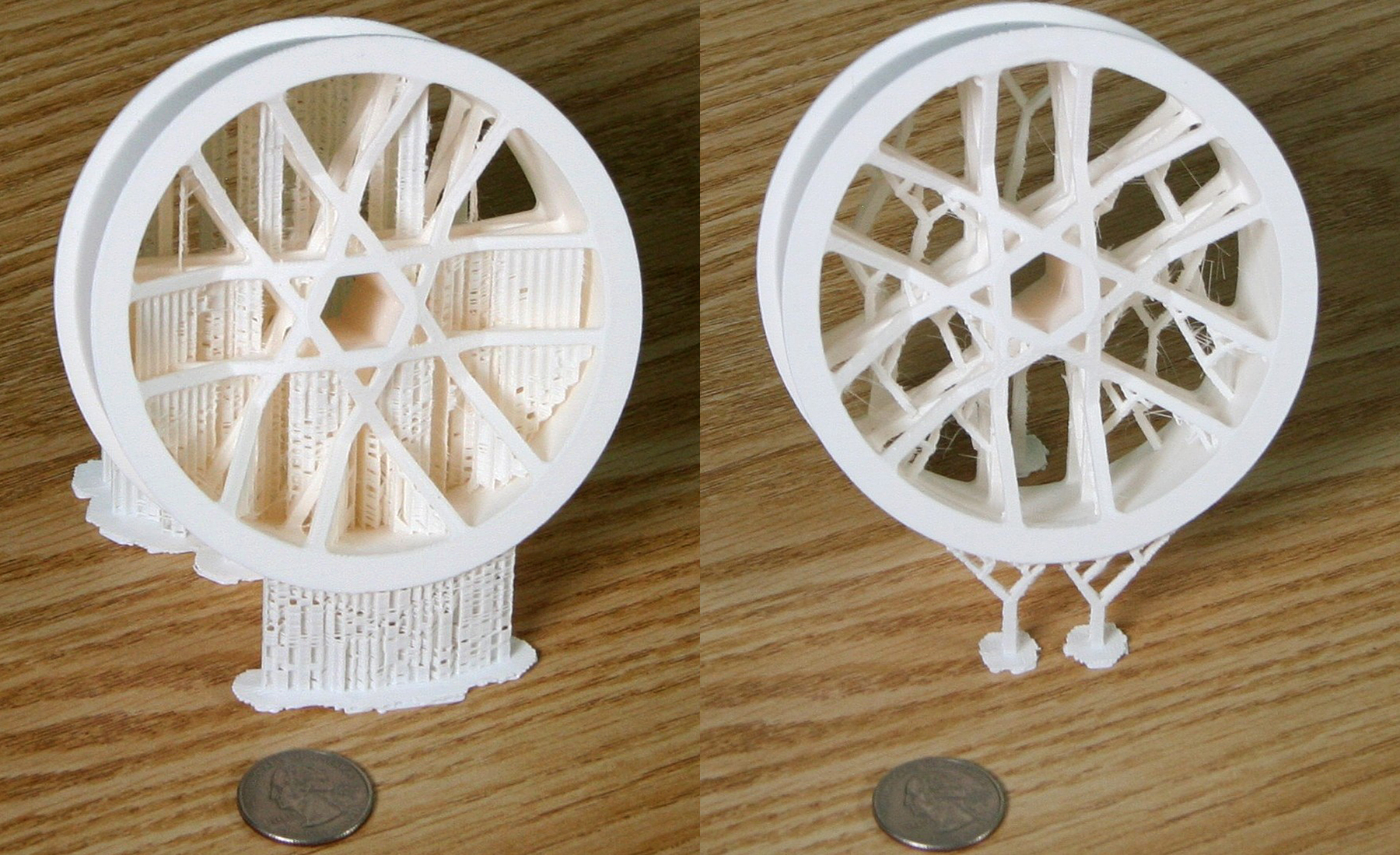

The FFF 3D printing method requires support structures for overhangs to be printed during the process, which will later be removed. This does not only add further material but also time to the 3D printing process. Researchers have now come up with algorithms that can save as much as 65% of support material for objects as well as up to 30% of printing time.

Two research papers have been published in the journal Computer Graphics Forum, detailing the new algorithms. Associate professor Bedrich Benes and his team have develop an algorithm that determines the orientation of the object before printing in order to minimise the required support structures.

“The computer automatically rotates the object in all possible orientations before printing to find the orientation that has the smallest overhang area,” Benes said.

The PackMerger algorithm determines how to pack the most elements into the smallest possible space using the same principle employed by the Tetris tile-matching puzzle game, in which tiles are manipulated with the aim of creating a horizontal line of blocks without gaps. “Our algorithm cuts the project into small elements that will fit into the printing tray,” Benes explains.

“The main advantage of it being geometry based is that it saves time and money and printing material.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.