Scientists at Bristol University have developed a new bio-ink for 3D printing with stem cells, that allows for bioprinting to create living tissue. This could eventually lead to the production of complex tissues for surgical implants.

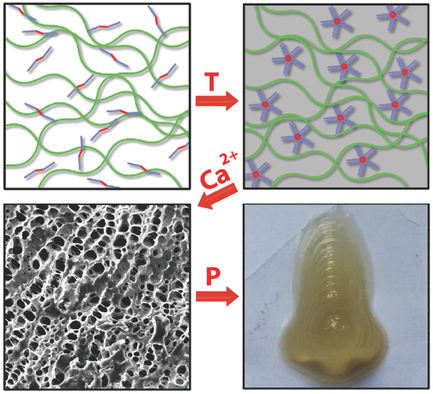

Bio-inks are difficult to create, as the material must be printable yet strong enough to maintain its shape. The new bio-ink created by Bristol researchers contains two different polymer components; a natural polymer extracted from seaweed and a sacrificial synthetic polymer used in the medical industry. Both play a unique an important role for bioprinting. While the synthetic polymer causes the bio-ink to change from liquid to solid upon raising temperature, the seaweed polymer ensures the structural support that is necessary when immersed in nutrients.

Dr Adam Perriman, lead researcher at the School of Cellular and Molecular Medicine, explained: “Designing the new bio-ink was extremely challenging. You need a material that is printable, strong enough to maintain its shape when immersed in nutrients, and that is not harmful to the cells. We managed to do this, but there was a lot of trial and error before we cracked the final formulation.”

Extruded from a modified desktop 3D printer, the liquid material transforms to a gel at 37°C. The research team then differentiated stem cells into osteoblasts and chondrocytes to engineer the 3D printed structures over five weeks. Osteoblasts are cells that secrete the substance of bone while chondrocytes secrete the matrix of cartilage to be embedded in it. This way scientists were able to create a full-size tracheal cartilage ring.

“What was really astonishing for us was when the cell nutrients were introduced, the synthetic polymer was completely expelled from the 3D structure, leaving only the stem cells and the natural seaweed polymer“, Dr Perriman further explains. “This, in turn, created microscopic pores in the structure, which provided more effective nutrient access for the stem cells.”

The study “3D Bioprinting Using a Templated Porous Bioink” can be accessed here.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.