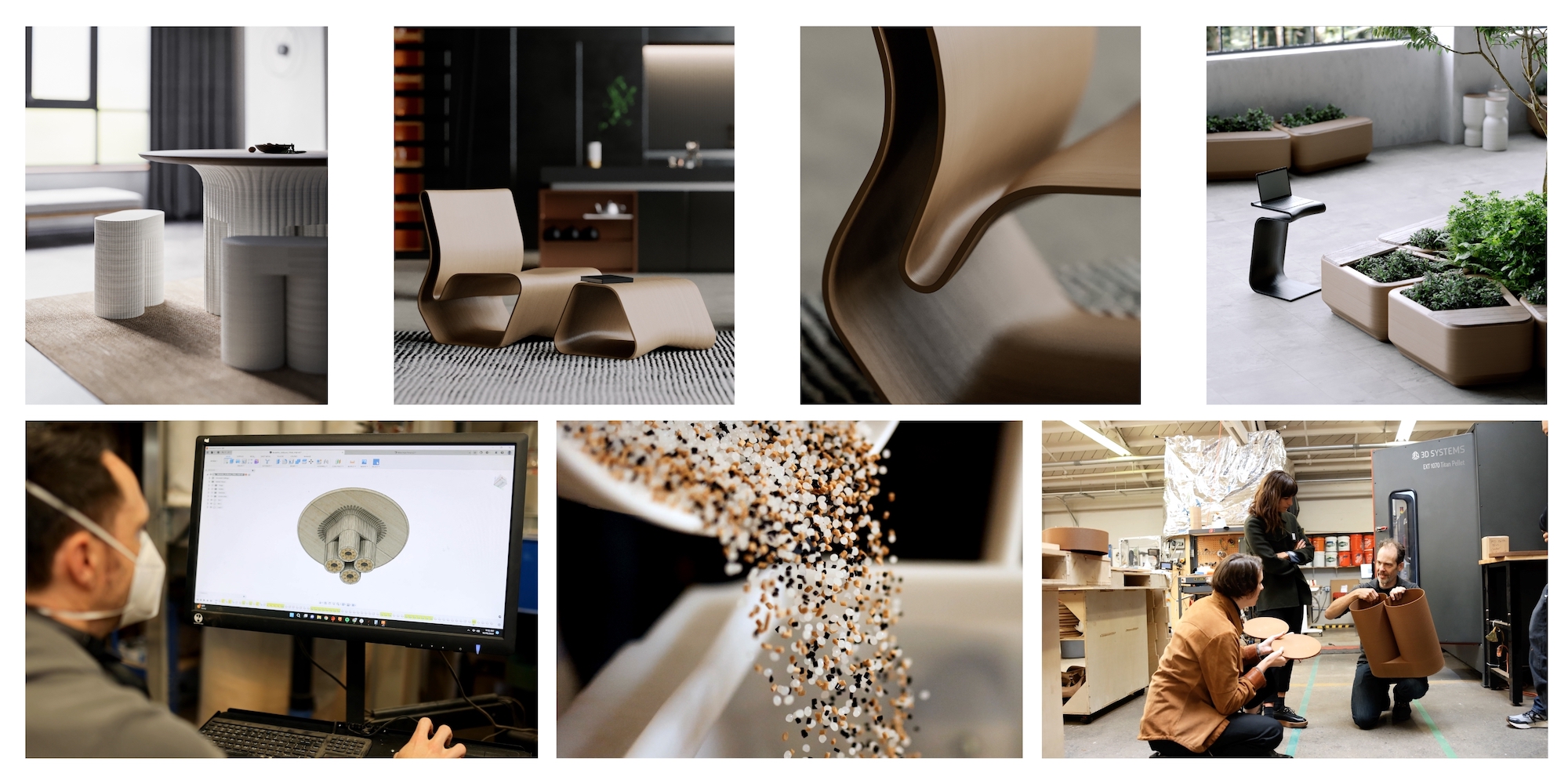

The furniture industry is on the verge of a paradigm shift, led by Model No. and 3D Systems, who have joined forces to produce sustainable, customized furniture pieces using advanced 3D printing technologies.

By using the EXT Titan Pellet printers, plant-based waste is converted into high-quality printing material, enabling efficient, environmentally friendly production. This innovative approach, combined with the principle of on-demand manufacturing, represents a significant step forward in minimizing the environmental footprint of furniture manufacturing.

Model No., which was founded in 2018 with the aim of transforming the furniture market through locally produced, sustainable products, found that traditional 3D printing methods did not meet the requirements for speed and sustainability. Switching to pellet printing systems allowed the company to utilize its innovative bio-resin compositions while significantly increasing production speed.

“According to recent estimates, commercial interiors are remodeled about every five years. Most of the furniture for these interiors is made overseas from petroleum-based plastics using outdated manufacturing processes, shipped in containers and stored in huge facilities. After creating a lot of harmful carbon emissions and waste, most of the furniture ends up in U.S. landfills at the end of its life,” said Philip Raub, CEO of Model No. “We’re looking at systemic changes to these operations. At Model No., we have streamlined the furniture manufacturing process by introducing 3D Systems’ EXT Titan Pellet brand printers and using bio-resins and non-toxic materials.”

A key element of Model No.’s strategy is the “Endless Loop: From Waste to Wanted” approach. This involves using locally collected wood waste to create new, unique pieces of furniture that are not only aesthetically pleasing but also environmentally friendly. All materials used are renewable, biodegradable and recyclable, underlining the company’s vision of a zero-waste production cycle.

“In the future, these technologies will give our customers and brand partners the opportunity to develop after-life solutions for our products. In the meantime, we also offer our customers a take-back program,” explains Raub. “And everything we produce is waste-free because we use the most advanced large-format 3D printers from 3D Systems, which produce virtually no waste and are powered by solar energy.”

The digital manufacturing method allows Model No. to efficiently realize individual customer requests while avoiding warehousing and overproduction. The short lead times, combined with the ability to mass customize, demonstrate the efficiency of the on-demand production model.

“We manufacture everything on demand and domestically or, if possible, locally,” says Raub. “Our customers have the ability to customize their products or order from a pre-made catalog, eliminating warehousing and wasteful production.”

The partnership with 3D Systems has allowed Model No. to expand its production capacity and meet the demand for sustainable furniture solutions.

“Our partnership with Model No. began almost three years ago when the company approached us with their concept. It’s incredibly satisfying to see how far Model No. has come,” said Rahul Kasat, VP Titan at 3D Systems. “The company is a perfect example of the unique manufacturing applications that are possible with 3D Systems’ 3D pellet extrusion printers.”

Overall, the initiative by Model No. and 3D Systems marks an important step towards more sustainable, efficient furniture production, paving the way for further innovation in the industry.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.