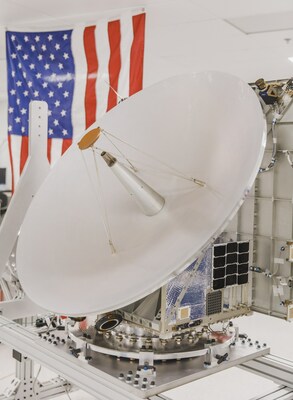

Vitesse Systems has announced the delivery of the first additively manufactured satellite antenna integrated into the Tomorrow-R1 satellite. The Tomorrow-R1 satellite was the world’s first commercially built weather radar satellite when it was launched last year.

The design and testing of the antenna was conducted at the Longmont site of Vitesse Systems (formerly known as Custom Microwave Inc.). Since acquiring the company in 2021, Vitesse Systems has invested in two additional metal 3D printers and expanded its design engineering capabilities to accelerate the development of complex antenna solutions. In addition, the company has developed a range of proprietary finishing processes that improve the surface properties of its antenna solutions, overcoming the limitations previously associated with additively manufactured antennas.

Richie Dart – General Manager, Vitesse Systems Longmont, explained, “Over the past few years, we have developed our additive manufacturing capability to optimize antenna performance and reduce development lead times. We initially focused on Ground and Airborne antenna applications, but it was always our intent to use this technology for Space hardware. Delivering our first additively manufactured satellite antenna is an important step on our technology roadmap and we look forward to more opportunities to leverage our additive capabilities for our customers.”

Dr. Clency Lee Yow – CTO, Vitesse Systems, added: “We began working with the team at Tomorrow.io back in 2020. As we developed the preliminary antenna design, we realized that we could optimize RF performance and reduce the overall mass of the antenna by using our additive manufacturing capability. Now that we have demonstrated that additive can be used in a space hardware application, it opens a broad range of other opportunities for Vitesse.

This development marks a significant advance in the use of additive manufacturing technologies for space applications and underlines the potential of these methods to improve the efficiency and performance of satellite components.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.