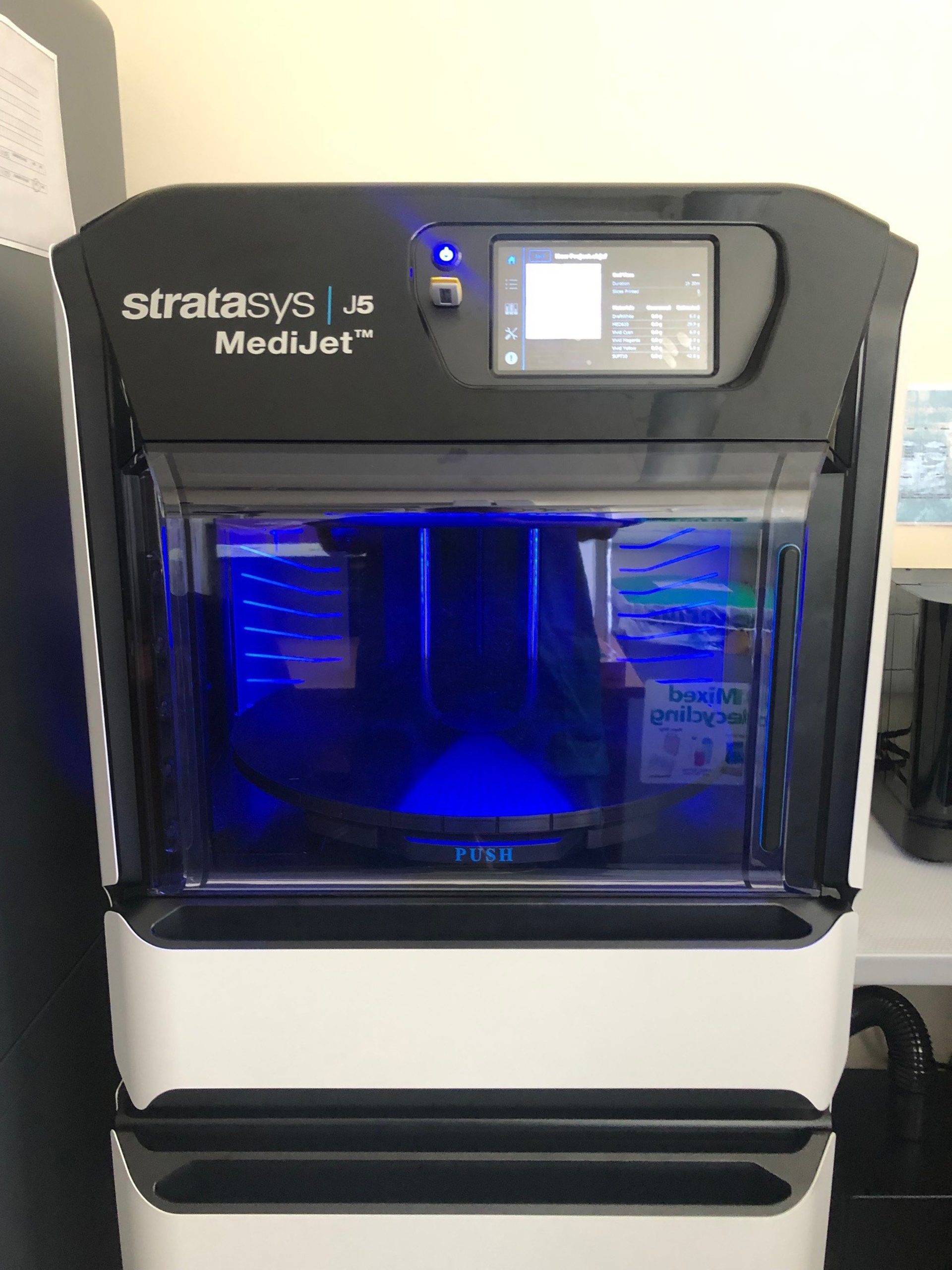

Birmingham University Hospital in England has reported significant improvements in the treatment of head and neck cancer patients through the use of customized 3D printed incision guides. This development is due to the integration of a Stratasys J5 MediJet 3D printer, which enables the hospital to create precise, patient-specific incision guides prior to surgery. This is transforming the way tumors are removed in head and neck cancer patients.

Through 3D printing, the surgical team can now produce highly accurate devices based on patient scans with a resolution of up to 150 microns, which supports surgical outcomes. These are made from Biocompatible Clear MED610™, a rigid, transparent resin suitable for applications with long-term skin contact (over 30 days) and limited contact with tissue, bone or mucous membranes (up to 24 hours).

“In addition to saving up to three hours of surgery time, 3D printing also enables much better surgical planning,” says Stefan Edmondson, Consultant Clinical Scientist (Reconstructive Science) at the hospital. “Using patient scans, the team is able to create 3D visualizations based on the distinct anatomy of each patient – and then leverage 3D printing technology to produce both anatomical models and personalized surgical cutting guides ahead of the actual operation.”

“This capability means we can not only accurately predict the surgery before it’s done, but that we have the tools to ensure that the meticulous pre-surgical planning can be executed with the utmost precision,” explains Edmondson. “The surgical team is also much better prepared and the patient is far more at ease, as we can talk through the process and expected outcomes prior to going into the operating theater,” he adds.

The precise creation of these cutting guides is particularly important when transplanting bone from a patient’s fibula into the head or neck. Inaccurate angles when cutting could result in the bone not fitting and being rejected by the body, causing significant discomfort for the patient. However, the 3D-printed cutting guides are accurate down to the micrometer, ensuring an optimal fit.

“In this scenario, if the angles you’re cutting at aren’t absolutely perfect, the bone won’t fit and there will be a higher tendency for the body to reject it, leading to significant discomfort for the patient,” continues Edmondson. “Thankfully, the 3D printed cutting guides are accurate to micron level, ensuring the fibula is cut to the best possible fit for our patients.”

Stratasys’ GrabCAD Print software, which is used in conjunction with this printer, has also proven to be beneficial. Its ability to automatically generate support material contributes to the overall time savings made possible by the 3D printing workflow.

University Hospital Birmingham, a pioneer in the use of additive manufacturing for medical applications, has many years of experience with various Stratasys 3D printers and technologies.

“Stratasys is the gold standard of 3D printers – something that is exemplified in the J5 MediJet,” adds Edmondson. “Beyond its ability to produce highly accurate cutting guides and brilliantly vivid anatomic models that are biocompatible and sterilizable, it is really easy to use, which makes it a winner with our team.”

Launched in 2021, the J5 MediJet allows users to create multi-material and full-color prints in a single tray. Hosted on an office-friendly platform that reduces outsourcing costs or eliminates the need for multiple printers, the system is designed to maximize reliability and simplify maintenance.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.