A lot of people need orthopaedic insoles for their feet but the production process of these is very complicated, costs a lot of money and takes a big amount of time. Cryos Technologies and Fuel3D have now developed a 3D scanner especially for feet that should help overcome the problems related to the current technique.

The Cryoscan3D should be able to scan a complete foot in less than a second. Cryos Technologies and Fuel3D have a special partnership for this high-tech 3D scanning device. Together the two companies have acquired a lot of experience in 3D scanning techniques in the past few years.

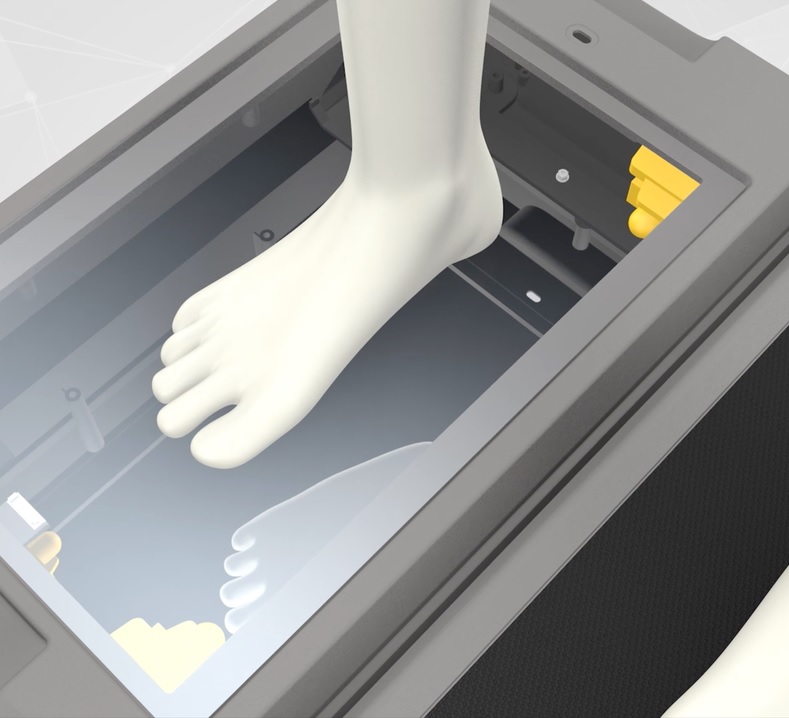

For the 3D scan the foot has to be pressed onto a “suspension membrane”. The membrane is there to ensure the foot is not pressed onto the glass plate because when this happens the 3D scan is useless for this application. To perform the 3D scan, Cryoscan3D uses a few cameras and lighting elements. The cameras take pictures of every side of the foot. These pictures are then transferred to the computer through an USB cable. The computer calculates an 3D model based on the different pictures.

With this technique a grade of detail of 0.250 mm is possible and the whole scanning process takes only 0.1 seconds. With the created model an orthopaedic insole can be produced – this can be done with conventional techniques, with 3D printing or with a combination of both.

Cryscan3D saves a lot of time and allows very detailed scans of feet. But it’s not yet known how much a Cryscan3D costs and when it will be released to the market.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.