YIZUMI Germany has developed with the SpaceA C-Line an innovative system enabling fully automated production of customized 3D-printed illuminated letters in batch size 1. This technology revolutionizes the manufacturing of large illuminated letters for shopping centers, hotels, and businesses, which was previously labor-intensive and costly.

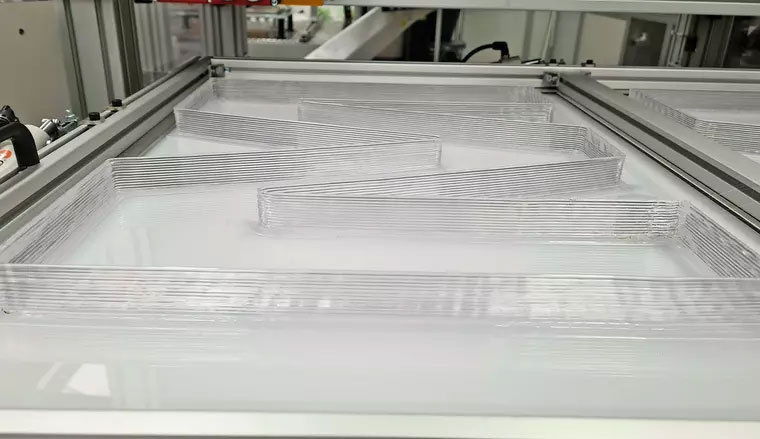

Traditionally, such letters were milled from solid PMMA sheets, resulting in significant material waste and time-consuming processing. With YIZUMI Germany GmbH’s new system, the letter’s sidewalls are automatically 3D-printed and mounted on a thin PMMA base plate. This approach significantly reduces material consumption and shortens production time to an average of just six minutes per letter.

The production facility comprises a central handling station, two 3D printers for the sidewalls, and a milling machine for finishing. A key feature of the system is its automated programming and control, which receives order data from the SAP system and efficiently coordinates production processes.

The challenge was to flexibly automate the various manufacturing processes. Through careful development of order data management and the use of sensors and monitoring technologies, YIZUMI achieved a highly productive and reliable solution.

This project showcases the strengths of German engineering and innovation. It also underscores the importance of efficient automation solutions for the competitiveness of European companies in the global industry.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.