Aircraft manufacturer Boeing has patented an additive manufacturing process where objects are created levitating in space. The patent titled “Free-Form Spatial 3-D Printing Using Part Levitation” was filed with the U.S. Patent and Trademark Office on February 4, 2016.

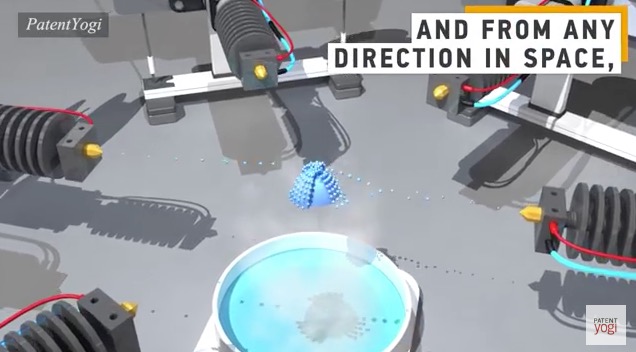

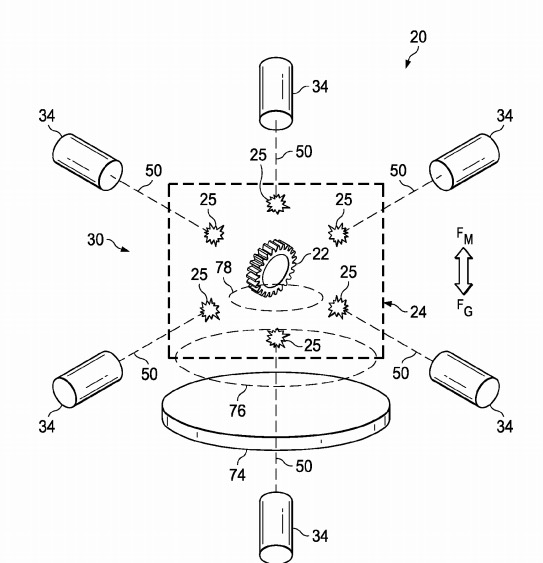

It describes the process of multiple 3D printers depositing material on a levitating object from several directions. Moreover, the floating object itself, that is held by a magnetic field, can be moved or rotated to any angle as well.

This is a completely new approach of 3D printing, unlike any other we have seen before. Usually objects are created bottom-up on a platform, whereas in the process patented by Boeing new layers of diamagnetic material can be added from all directions, allowing for complex parts to be created. Moreover, no support structures are needed. According to the patent the method works for both new as well as existing parts. Due to multiple print heads being used, the “nuggets”, as Boeing calls the printed objects, can be created at a much higher speed.

The patent’s abstract: A part is fabricated by an additive manufacturing process while levitating in space. Constituent features of the part are formed by 3-D printing. A part levitation system allows the spatial orientation of the part to be manipulated relative to one or more print heads.

PatentYogi has created a video of Boeing’s futuristic technology:

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.