As demand for additive manufacturing processes continues to grow, BOFA’s filtration technology is now in demand to support the post processing environment that is key to productivity.

Post-processing in the world of 3D printing is an important step in the production chain and is vital to transforming the commercial potential of additive manufacturing into high-quality finished products.

As Luke Ziolkowski, International Business Development Manager, BOFA International explains: “Post-processing is a catch-all term and means different things to different manufacturers – but the ultimate aim is the same… to create a product ready for market. This typically includes curing, polishing, deburring, mechanical cleaning or air blasting – all of which emit particles or gases that require BOFA filtration to help maintain a healthy working environment and to contribute to a high-quality end product.”

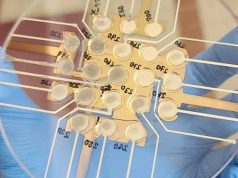

BOFA is responding to demand with a number of 3D print filtrations systems that are suitable for post processing environments. These include the FumeCAB enclosure technology which is ideally suited to a stereolithography system where the off-gassing from the print gets extracted. It can also help with the off-gassing from a washing station and contribute to filtration for most other post-processing applications.

BOFA’s 3D PrintPRO 4 has recently been enhanced to support fused deposition modelling, stereolithography, digital light processing, and material jetting. It can manage multi-unit operations thanks to an advanced, high-capacity filtration system, while delivering optimal temperature control. Effective airflow management contributes to an odourless workplace environment.

Finally, the AD Oracle iQ is a high-performance global fume extraction system designed for laser marking, coding engraving and AM laser sintering applications. BOFA’s latest generation iQ2 intelligent operating system features a host of functionality enhancements and innovations, including extended onboard data logs and real-time system condition visualisation. iQ2 also supports a colour touchscreen user interface, smart alarm configuration and system upgrades.

BOFA International will be showcasing some of its latest innovations in 3D printing filtration and atmosphere management at Formnext 2022 in Frankfurt (November 15-18), with BOFA representatives available on stand 12.0-E18.

Mehr über BOFA International finden Sie hier.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.